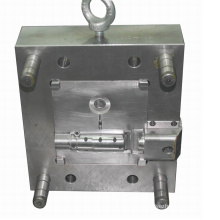

High quality LKM HASCO mold base injection mold service

Product Description

High quality LKM HASCO mold base injection mold service

Advantages of Injection Plastic Parts

- Competitive price

- Continuance service and support

- Diversified rich experienced skilled workers

- Custom R&D program coordination

- Application expertise

- Quality,reliability and long product life

- Mature,perfect and excellence,but simple design

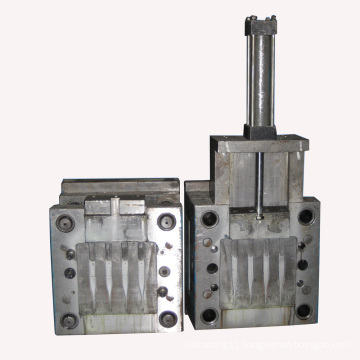

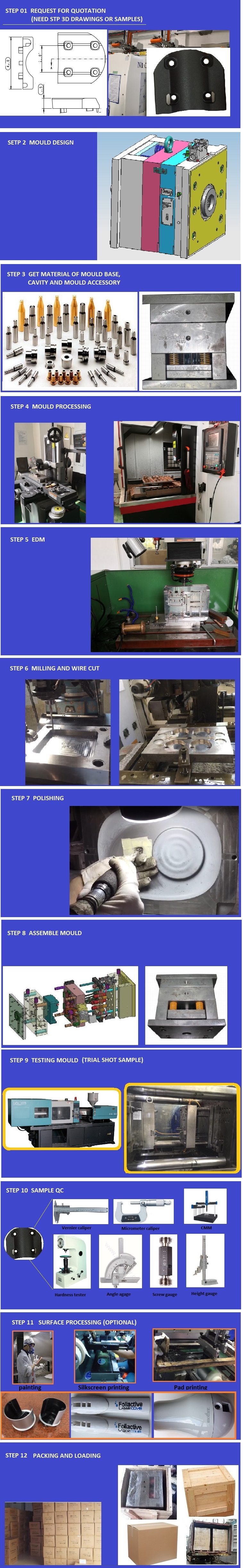

Steps of injection Plastic Parts

- Negotiations: Quality,material,price,payment,delivery time item and so on

- Place an order: According customer's drawing or sample

- R&D: According customer's requirements,we could design or improve 3D modeling

- Design confirmation: We send 3D drawing to customer for confirmation before we make the mould

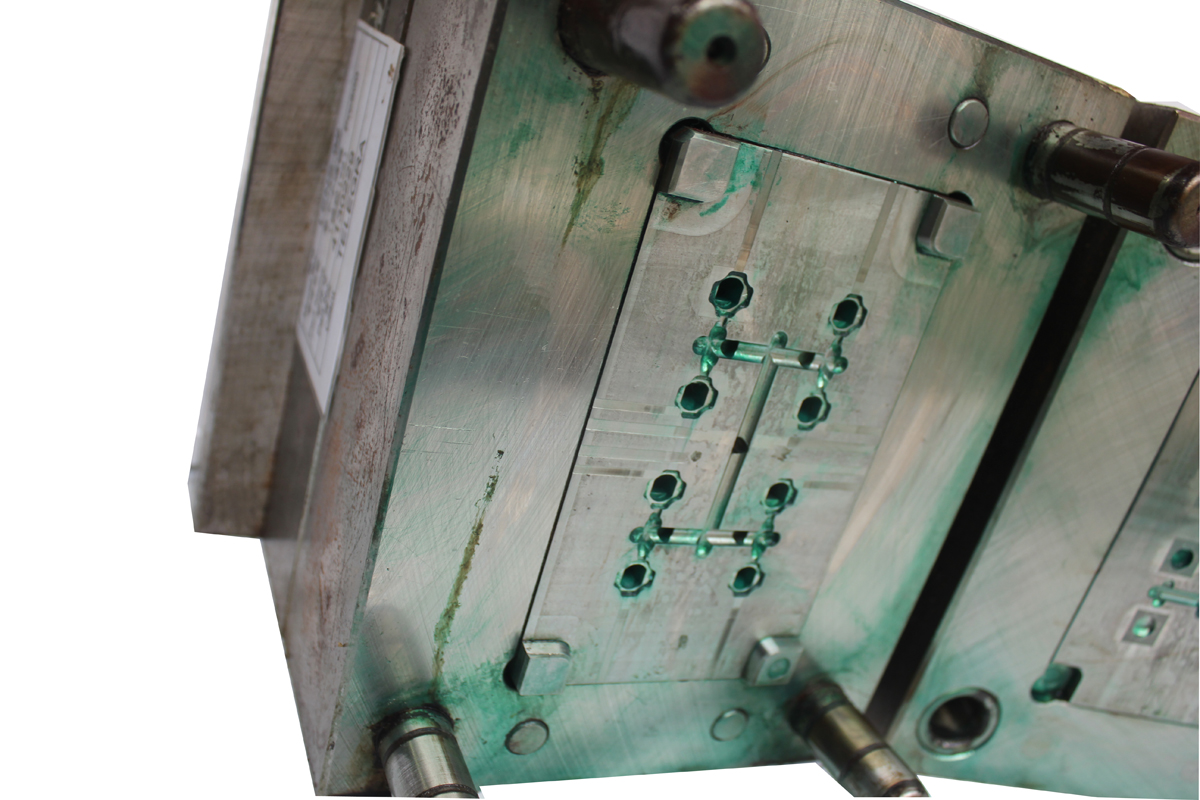

- Mould processing: CNC EDM machine processing then assembly and trial

- Sample confirm: We will send trial sample to customers.Before shipment,If the sample isn’t satisfied by customers.We will modify mould until they are satisfied.

- Mass production: If customers need mass production of plastic products,We can offer

- Manufacturing Package and Delivery

Specifications of injection plastic parts:

| Products Name | High quality LKM HASCO mold base injection mold service. (We design and manufacture plastic injection molds Auto Parts, home applications, medical products, Household commodities, consumer electronics, mobile phone parts and accessories, and many other kinds of molds in different fields. ) |

| Working Process | Plastic injection |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/ high volume plastic production |

| Design Software | UG,Pro E Solidwork,AutoCAD, etc |

| Core&Cavity Material | Steel, H13, S-7,P20,718,2738,NAK80,718H, S136, etc |

| Mold base | HASCO ,DME ,LKM,JLS standard |

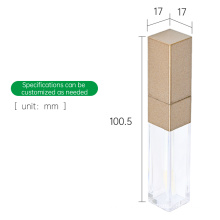

| Mould Cavity | Singe or multi cavity |

| Mold strandard parts | DME, HASCO, etc. |

| Runner | Hot runner, Cold runner |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Mold cold runner | Side gate,Sub gate,Pin point Gate... |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| plastic Injection Machine | 10sets,110T,140T,160T, 200T,260T,320T |

| Plastic Material | PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| MOQ | 1set for mold ,plastic products as per your request |

| Mold Life | 300000-500000 shots as per customers' requirement |

| Inspection | As customers’ requirements |

| Delivery | Air cargo, Sea shipping |

| Lead time | 25-45 workdays based on the different products |

| Inspection | IQC, IPQC,FQC,QA |

| Quality Control | Conducted by ISO9001 |

A&R is founded in 2004, with around 14years experience. We are mainly engaged in R&D mold and product design,molding, plastic injection parts and assembling, covering various fields, covering automotive, electronics,medical, industry and toy parts.

For production, we have inhouse facility to process CNC, milling, grinding, EDM, Wire-cut, as well as injection molding.

Our company is positioned in the middle and high end market in order to guarantee the high precision requirements.We have strict quality team to make sure what our customers received are the best molding products for their new products.

High quality LKM HASCO mold base injection mold service

| Service | 1.CNC Plastic/Metal Prototypes |

| 2.Low Volume Production | |

| 3.Rapid Hardware/Sheet Metal Prototypes | |

| 4.CNC Aluminum/Brass/Copper/Bronze CNC machining | |

| 5.SLA/SLS prototype | |

| 6.3D Printing | |

| 7.Electronic Manufacturing Service | |

| 8.Injection mould&Plastic Injection | |

| 9.Design service (OEM service) | |

| Certification passed | Bureau Veritas,ROHS,ISO |

Q. How can I get the accurate price?

A. There are some basic specs we need to know for price calculate, that are:3D drawings in STP, IGS, X-T format are avaialble, Please suggest us your quantity too.

Q: Are you trading company or manufacturer?

A: We are factory.

Q I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials tooling and likely set-up costs.

Q What type of mould tool do I need?

A Mould tools can be either single impression (one part at a time)or multi-impression(2, 4, 8 or 16 parts at a time). Single impression tools are generally used for small quantities, up to 10,000 parts per year whereas

multi-impression tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q If I've decided to go ahead with my project. How long will it take to get the trial shot sample?

A. It will take 3-8 weeks to have the tooling manufactured which depend on the part's complexity and the number of impressions(single or multi). After the tooling is completed, you can expect delivery of trial shot samples within

2-3 days.

Product Categories : Mold & Moulding > Mold & Moulding

Premium Related Products