High quality Plastic Injection Molding/moulding factory For Medical Plastic Parts

Product Description

High quality Plastic Injection Molding/moulding fact

ory For Medical Plastic Parts

We have professional engineers design team,and can use CAD,Pro-E,UG,Solidworks etc.

Before the project started:

1, If you have 3D STEP/IGES/X_T drawing or 2D drawing, please directly send to us

before quotation, then we will do DFM and mould design for you.

2, If you have samples no drawings, please directly provide us samples, we can design

3D for you,and quotation.

Production details:

| Part name | High quality Plastic Injection Molding/moulding ABS/PA/PP/PC Factory For Medical Plastic Parts |

| Products Variety | We design and manufacture plastic injection molds auto parts, home applications, medical products, Household commodities, consumer electronics, mobile phone parts and accessories, and many other kinds of molds in different fields. |

| Main services | 3D design, Prototypes, Mold design, Mold making, Mold tesing, Low volume/ High volume plastic injection production |

| Design Software | UG,Pro E Solidwork,AutoCAD,Moldflow.... |

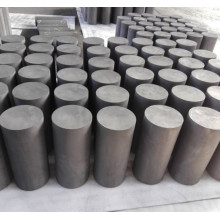

| Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13.... |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mould Cavity | Singe or multi cavity |

| Mold strandard parts | DME, HASCO, etc. |

| Runner | Hot runner, Cold runner |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Mold cold runner | Side gate,Sub gate,Pin point Gate... |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| plastic Injection Machine | 10sets,110T,140T,160T, 200T,260T,320T |

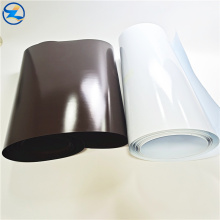

| Plastic Material | PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| MOQ | 1set for mold ,plastic products as per your request |

| Mold Life | 300000-500000 shots as per customers' requirement |

| Inspection | As customers’ requirements |

| Delivery | Air cargo, Sea shipping |

| Lead time | 25-35days for mold,plastic products according to quantity |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2 .Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold(moulds) | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production. |

| 7. Package | Wooden case for moulds, cartons for parts ,or as your requiretment. |

| 8. Delivery | deliver goods by air or by sea. |

Established in 2002, Shenzhen A&R Technology Co., Ltd mainly specializes in the design,molding, plastic injection parts and assembling covering a variety fields.We have facilities of plastic mould & injection, silkprint, Assembly. So we are capable of supply the package service from the design to manufacturing of various electronic products and home appliances.

Product Range:

Electronic: sensor, USB housing, etc

Mobile phone plastic part, remote control, key-press, fingerprint head, handle, cover

Mechanical: Junction box, Motor support part, Pump plastic part

Household: Industrial number calculator part, Juice cup, safety helmet

Medical: hearing aids, Hollow fiber Dialyzer, Blood-Pressure meter, Stapler

Sport: Golf plastic part

Office: Secret code case part, Printer, duplicator, Atom seal

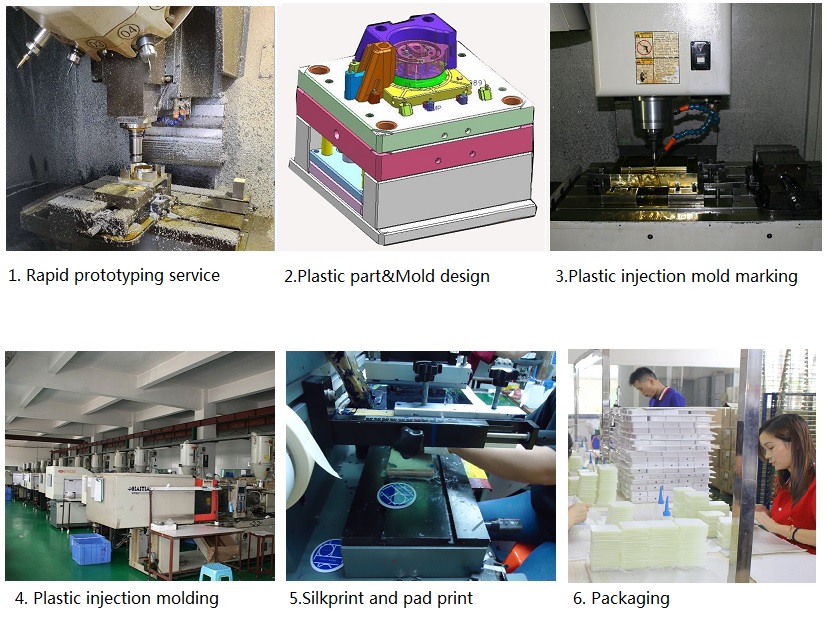

We offer the whole solution of service as following:

1, Part design assistance (with our suggestions you can save the mold cost)

2, Prototype

3, Mold design

4, Mold manufacturing

5, Mold test

6, Mold modification

7, Plastic part injection molding

8, Painting, silk screen, assembly

9, Packaging and delivery

Our Advantage:

-16years manufactoring&exporting experience

-One stop serevice for plastic parts, moulds and assemblying.

-we have 5experienced engineer, 3 administrative people, 5 QC.

-With the objective of responsible and professional service, quality products, fine price, on time delivery.

-can accept small order with good service,customer can find us at any time,we can give design or production suggestion

Our Service:

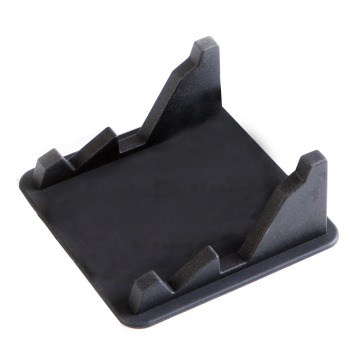

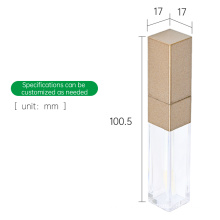

Product Show:

Product Categories : Mold & Moulding > Mold & Moulding

Premium Related Products