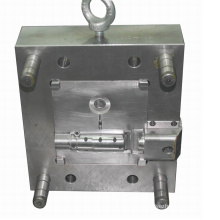

Copper Alloy Casting

Product Description

Material: Copper Alloy Brand Name: Customized or Stk Trademark: STK Origin: Xiamen, China Place of Origin: Fujian, China (Mainland) Served Industry: Auto Parts, Medical Appliance, Consumer Electronic Specification: ISO 9001: 2000 HS Code: 39199090 Product Name: Copper alloy casting

With abundant experience of more than 10 years, we are professional in producing aluminum Die Casting, zinc die casting and copper die casting.

Copper Die Casting is widely used by clients for the smooth functioning of motors. Manufactured using copper alloys, these copper casting dies find extensive application in engineering, construction and automobile industries.

1. Silicasol process precision casting and soluble glass precision casting

2. Material: Stainless steel casting, carbon steel casting, alloy steel casting

3. Certificate: DIN, AISI, ASTM, BS, JIS, ect.

4. Heat Treatment, polishing, plating, machining, ect.

5. Application: Industrial parts, Machinery Parts, hardware, construction parts, valve/valve parts.

If any questions, please feel free to contact us at any time. Welcome to visit our our website for More Products information. If you are interested in my offers, please send me your detailled information such as your drawing and detailed specifications, chemical composition, etc, hope we could have a very nice start and build long-term relationship.

Contact us if you need more details on Copper Alloy Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Copper Die Casting Parts、Copper Alloy Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

With abundant experience of more than 10 years, we are professional in producing aluminum Die Casting, zinc die casting and copper die casting.

Copper Die Casting is widely used by clients for the smooth functioning of motors. Manufactured using copper alloys, these copper casting dies find extensive application in engineering, construction and automobile industries.

1. Silicasol process precision casting and soluble glass precision casting

2. Material: Stainless steel casting, carbon steel casting, alloy steel casting

3. Certificate: DIN, AISI, ASTM, BS, JIS, ect.

4. Heat Treatment, polishing, plating, machining, ect.

5. Application: Industrial parts, Machinery Parts, hardware, construction parts, valve/valve parts.

If any questions, please feel free to contact us at any time. Welcome to visit our our website for More Products information. If you are interested in my offers, please send me your detailled information such as your drawing and detailed specifications, chemical composition, etc, hope we could have a very nice start and build long-term relationship.

| Item name | copper alloy casting |

| Product description | 1. Material: Aluminum(6061, 6063, 7075), Aluminum alloy, A360, A380, A383, AlSi10Mg, ADC10, ADC12, ZL104, ZL107; 2. Process: Die Casting+Machining 3. Precision machining: CNC lathes, milling, drilling, grinding, etc. Surface 4. Finish: high quality polish, Chrome/nickek/Zinc(white, blue, yellow, black)plating, hot galvanized, painting, powder coating, Anodize, electrophoresis, sandblasting and ect. 5. Small quantity is also available 6. Production Leadtime: 7-30 days depending on the quantity of the order 7. The product in the prictures are our customers' OEM products, for reference only. |

| Advantage | 1. Our factory is specialized in doing OEM/ODM products according to customers' drawings or samples 2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001, CAXA, UG, CAD, CAM 3. Certificates: ISO 9001: 2000 4. Advanced equipment, excellent R& D teams and strict quality control system |

Product Categories : 9) Others

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts