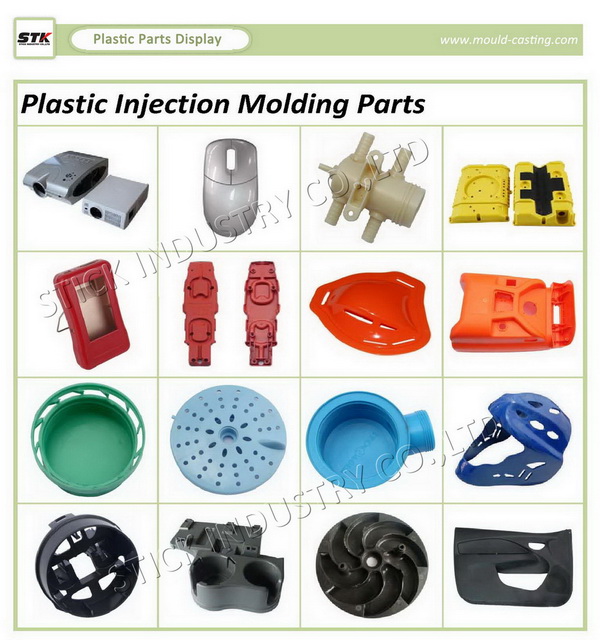

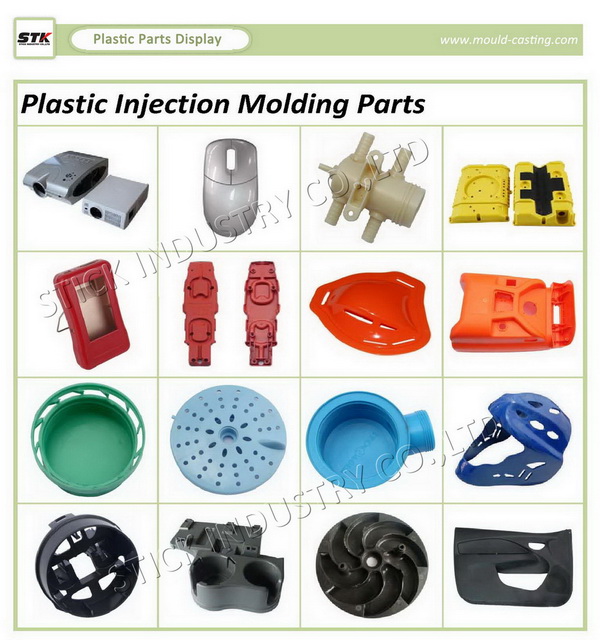

Various Plastic Injection Molded Components

Basic Info

Model No.: Component

Product Description

Model NO.: Component Process Combination Type: Compound Die Installation: Semi Fixed Finish: Color Painting, Texture, Silk Printing Mould Leadtime: 3-6 Weeks Trademark: Customized or STK Specification: ISO9001: 2000 HS Code: 3926909090 Shaping Mode: Injection Mould Application: Car, Household Appliances, Furniture, Electronic, Home Use, Hardware Material: ABS, PC, PS, PP, PVC, TPR, TPU, TPE, etc Certificate: FDA, RoHS Mould Life: 100, 000-1, 000, 000 Shots Transport Package: Standard Export Packing or as Per Request Origin: China Product name: Plastic Injection Molded Component

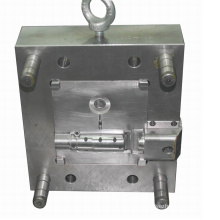

STK have a modern workshop combined with the use of 3D right from the design stage to finished product. We produce all kinds of moulds from small technical moulds to large moulds.

Our Professinal injection mold service:

1. Automobile mold

2. Gear mold

3. Cap mold

4. Unsrewing mold

5. Overmold, overmolding, Two Shot Over-Molding, Two Color Over-Molding, Insert Over-Molding

6. Hot runner mold

7. Injection molding

8. Stamping and die-casting mold

Please contact with us for getting more details of our service!

Contact us if you need more details on Molded Component. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Molded Component、Injection Parts Component. If these products fail to match your need, please contact us and we would like to provide relevant information.

STK have a modern workshop combined with the use of 3D right from the design stage to finished product. We produce all kinds of moulds from small technical moulds to large moulds.

Our Professinal injection mold service:

1. Automobile mold

2. Gear mold

3. Cap mold

4. Unsrewing mold

5. Overmold, overmolding, Two Shot Over-Molding, Two Color Over-Molding, Insert Over-Molding

6. Hot runner mold

7. Injection molding

8. Stamping and die-casting mold

Please contact with us for getting more details of our service!

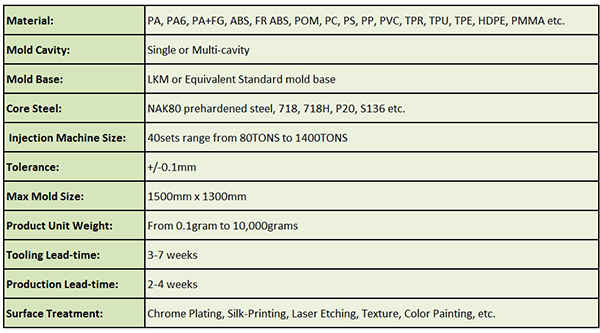

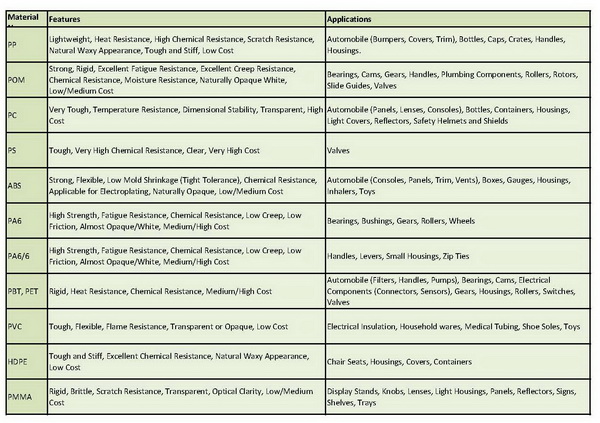

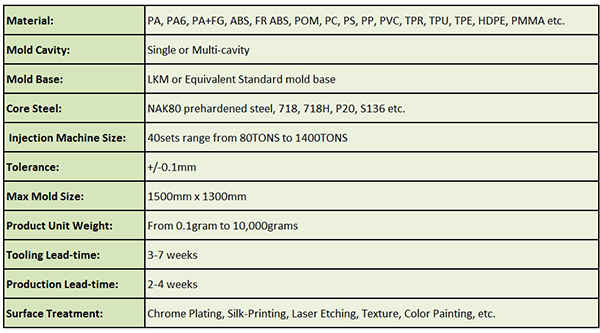

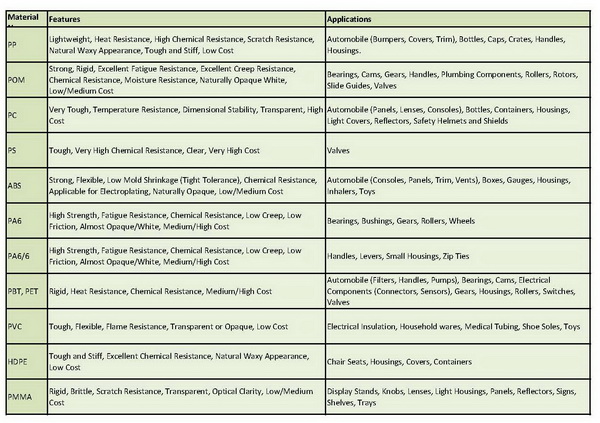

| Item Name: | Plastic Injection Molded Component |

| Product Description: | 1. Material: ABS, flame-resistant ABS, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc 2. Mould Cavity: Single or multi-cavities 3. Mold base: LKM or Equivalent standard mould base 4. Core Steel: NAK 80 prehardened steel, 718, 718H, H13 etc. 5. Surface Finish: chrome plating, silk-printing, Laser etching, texture, color painting etc. 6. Injection Matching Size: 20 sets range from 120T To 850T 7. Max Mould Size: 1700× 1700mm 8. Max Product Size: 1200× 1200mm 9. The product in the pictures are our customers' OEM products, for reference only. |

| Company Profile: | With plentiful experience and skillful technique, Xiamen Stick Industry Co., Ltd. is specialized in doing double-injection molding, insert mould injection molding, plastic injection molding, one cavity and multi-cabity molding, plastic mold, etc in china. Our company is capable to produce Plastic Parts as per your drawings/ samples, and we also enjoy good reputation among our domestic and overseas market. |

| Company Advantage: | 1. ISO 9001: 2000 certified 2. Advanced equipment and excellent R& D Team 3. Highly skilled manufacturing process 4. A broad variety of ODM& OEM product range 5. Strict quality Control System 6. Software for specification drawings: Pro/E, Auto CAD, solid work 2001, CAXA, UG, CAD, CAM |

Product Categories : 3) Plastic Injection Parts

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts