OEM High Precision Iron Sand Casting and Steel Die Casting

Basic Info

Model No.: STK-ZDO0025

Product Description

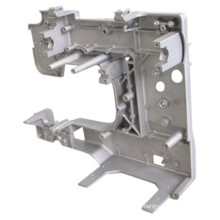

Model NO.: STK-ZDO0025 Casting Form Material: Sand Surface Treatment: Electroplating Coating: Zinc oxide Certification: SGS, ISO 9001:2000 Application: Industrial Parts,Marine,Aerospace,Electronics,etc Service: OEM ODM Trademark: Customized or STK Specification: According To Your Required HS Code: 8308900000 Casting Method: Sand Casting Casting Metal: Cast Iron Surface Roughness: Ra0.05 Machining Tolerance: +/-0.01mm Material: Carbon Steel, Stainless Steel Process: Precision Die Casting Color: Silver, Black, Gold Transport Package: Carton, Crate or Based on Your Requirement Origin: China Product name: Iron Sand Casting And Steel Casting

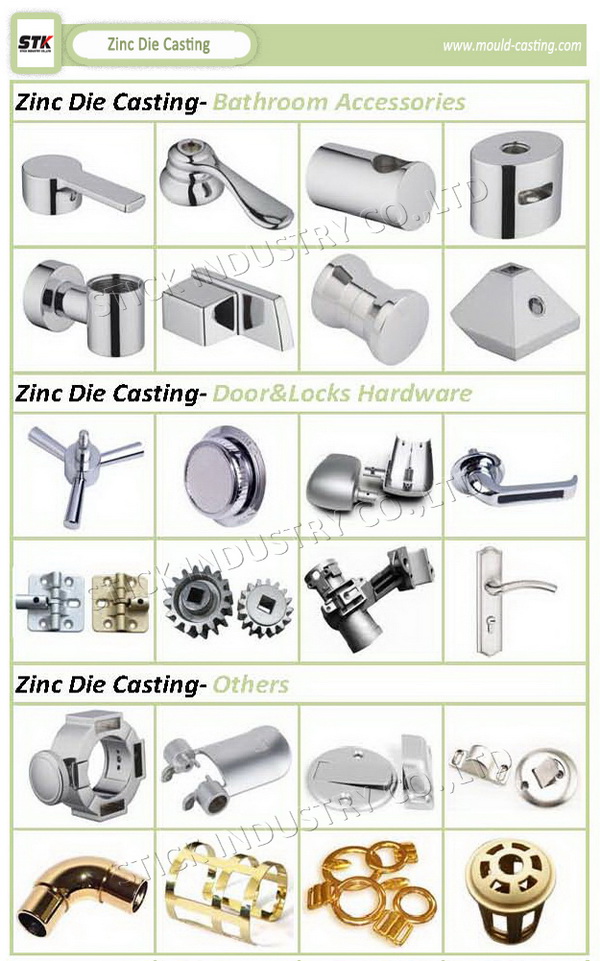

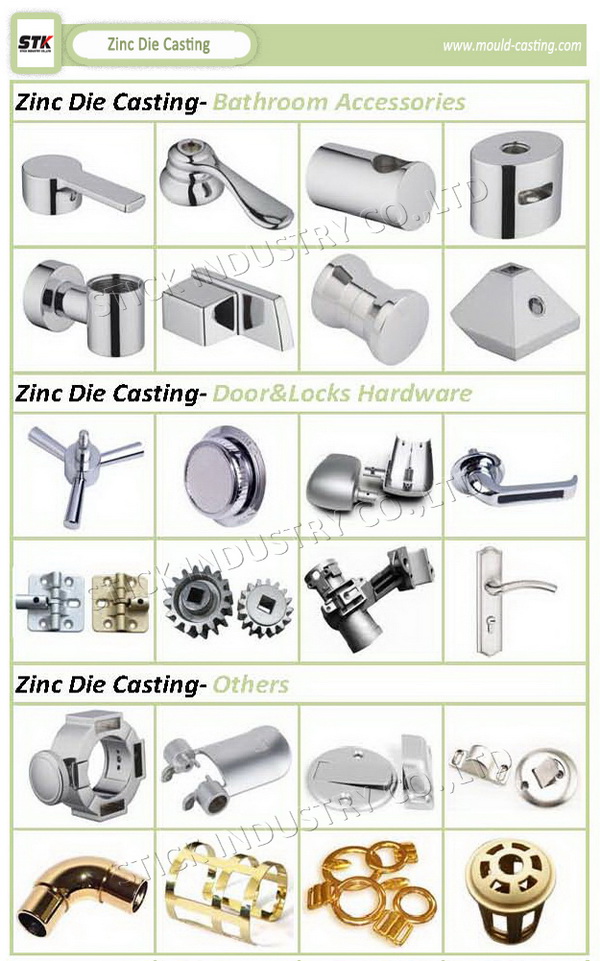

Specific Zinc Die Casting Capabilities

Automated equipment handles high volume casting jobs of up to 100,000 pieces per week

Manual machines for low volume jobs of minimum quantity of 500 pieces per year.

Can cast from 0.02KGS to 5KGS

Single to multiple cavities

6 sets of hot chamber die casting machines range from 88Tons to 280Tons.

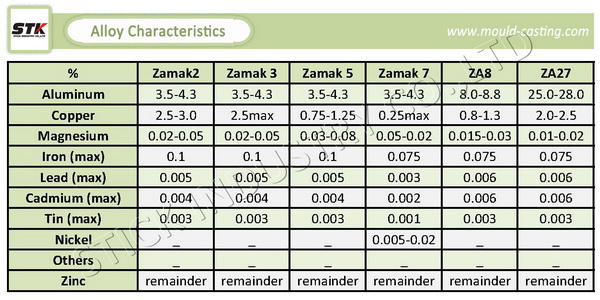

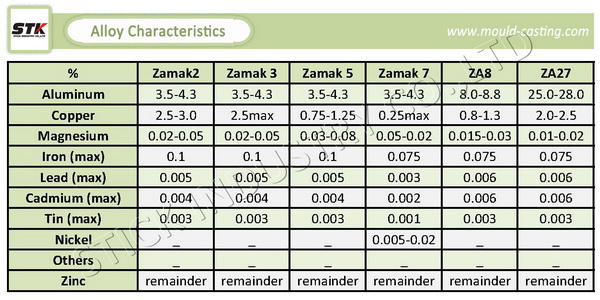

Most zinc casting alloys are offered such as Zamak2, Zamak3, Zamak5, Zamak7, ZA8, ZA27 etc.

Specializing in small, large, complex, precision components

1. Accurate dimension

2. Reasonable price

3. Small order accepted

4. Lead-time guarantee

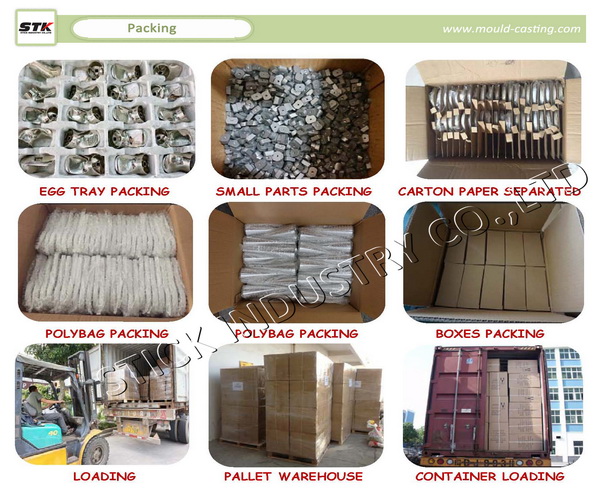

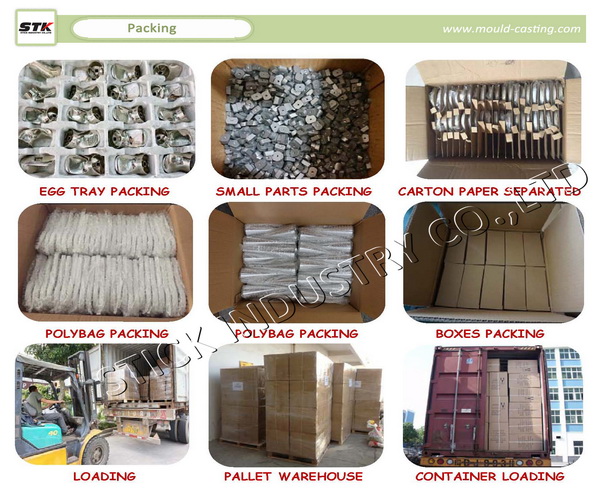

Contact us if you need more details on Sand Casting Process. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Sand Casting、Grey Iron Sand Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specific Zinc Die Casting Capabilities

Automated equipment handles high volume casting jobs of up to 100,000 pieces per week

Manual machines for low volume jobs of minimum quantity of 500 pieces per year.

Can cast from 0.02KGS to 5KGS

Single to multiple cavities

6 sets of hot chamber die casting machines range from 88Tons to 280Tons.

Most zinc casting alloys are offered such as Zamak2, Zamak3, Zamak5, Zamak7, ZA8, ZA27 etc.

Specializing in small, large, complex, precision components

1. Accurate dimension

2. Reasonable price

3. Small order accepted

4. Lead-time guarantee

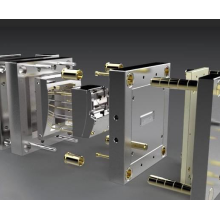

| Casting Parts | @ Sand casting @ Plaster casting @ Lost wax casting @ Investment casting |

| Materials | @ Aluminium casting: 319, 355, A356, @ Magnesium casting: A291D, AM60B @ Zinc casting: ZA-12, ZA-27 @ Grey cast iron @ Nodular cast iron |

| Production procedure | 1. Designing drawing 2. Opening mould 3. casting 4. Precision machining 5. Surface treatment: polish, electrophoresis, painting, anodizing, powder coating etc. 6. Inspection and packing |

| Application | @ Auto Parts @ Medical parts @ Machine parts @ Aerospace Machinery Parts @ Ships equipment parts @ Electrical parts @ Furniture parts @ Kitchen tools @ Telecommunications |

Product Categories : 1) Zinc Die Casting

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts