Customized Small plastic molding wheel, Portable PP wheel, Skate wheel rail accessory

Product Description

Customized Small plastic molding wheel, Portable PP wheel, Skate wheel rail accessory

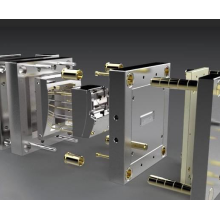

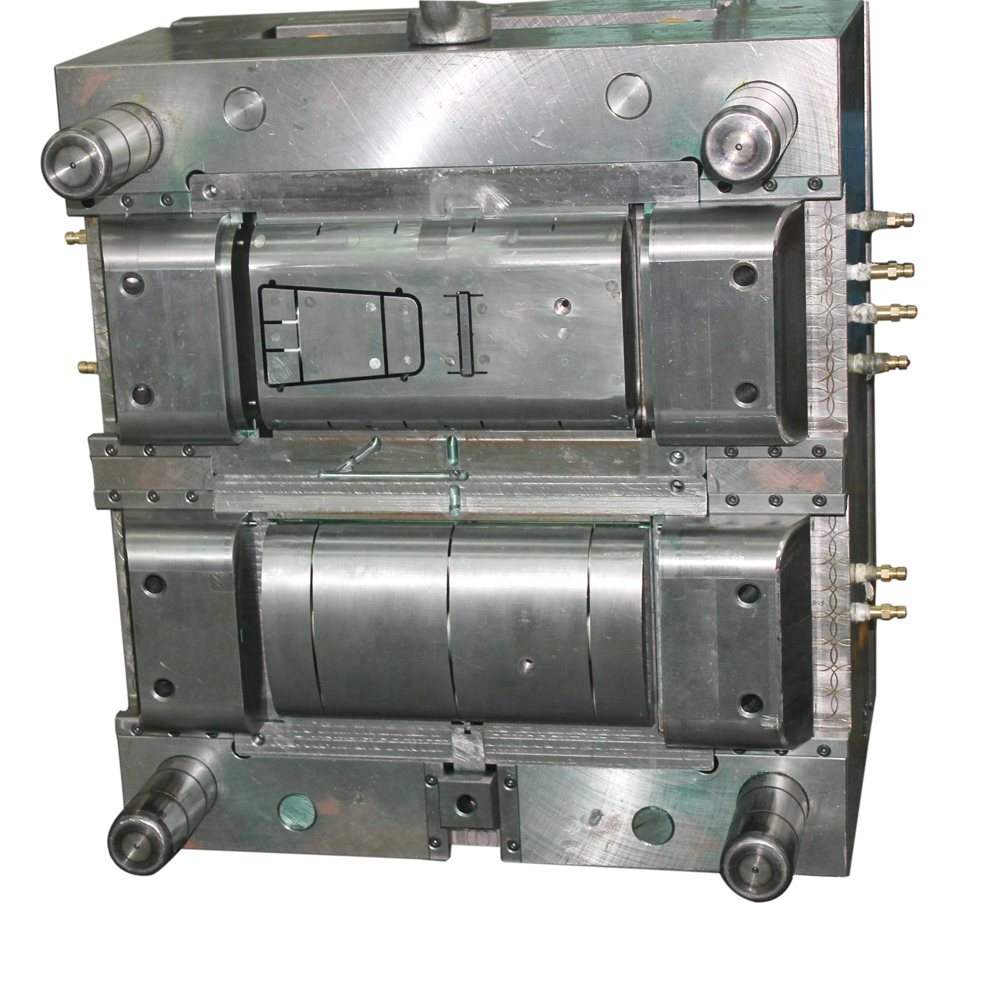

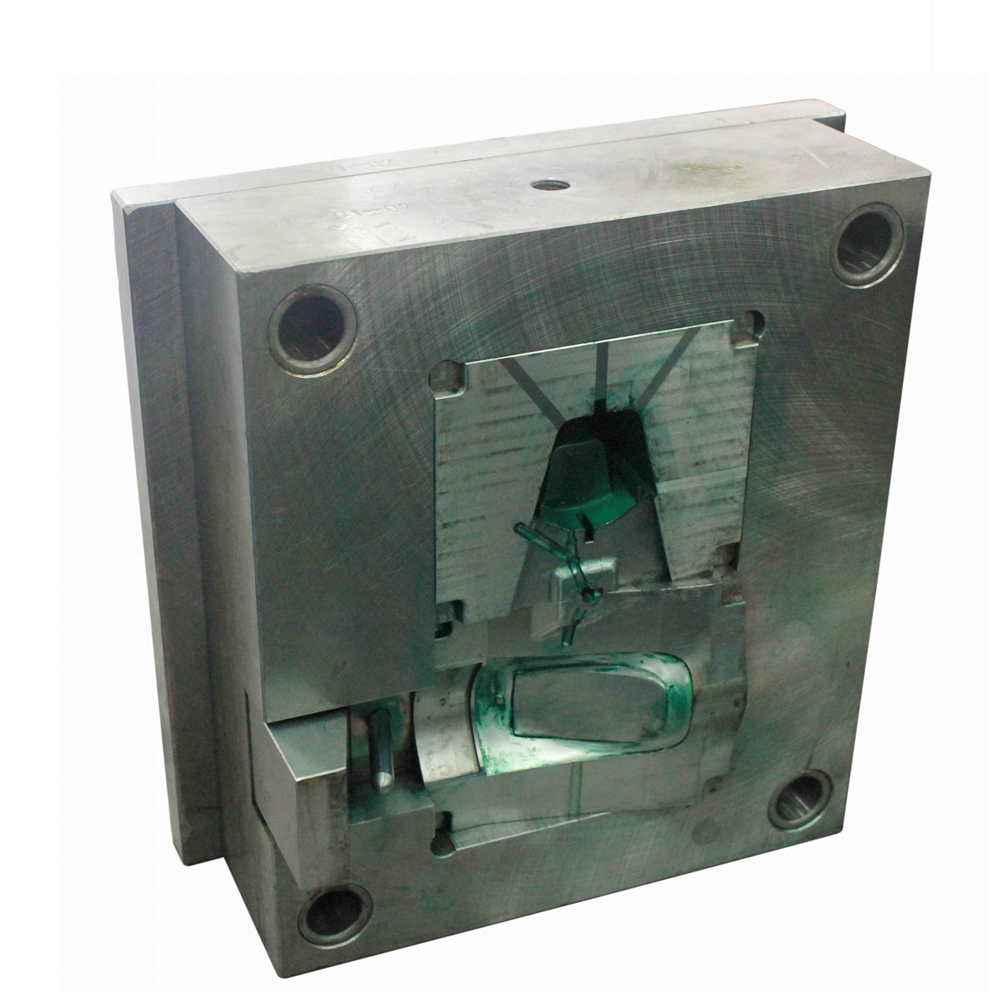

1. Mould base: LKM,HASCO,JLS,DEM

2.plastic injection tooling maker

3.samples to test quality

4.OEM service

All of our products can be customized. Any sizes, shapes, designs, logos meet your requirement,before quote you the price ,we will be appreciated if you can provide the information below:

1. Bag type.

2. Material structure and thickness.

3. Application of the packaging.

4. Bag size(Width & Length & Gusset).

5. The printing area and color.

6. If possible,pls provide the picture or artwork of the packaging,If you are not clearly , we will recommend for you.

With above information we can quote exact price immediately.

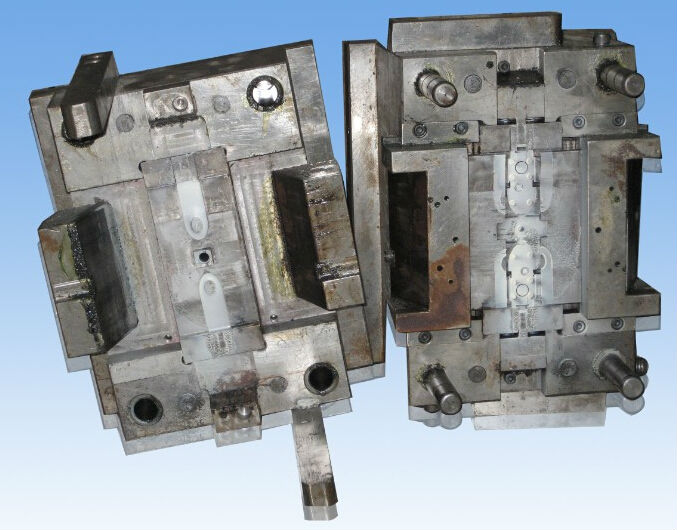

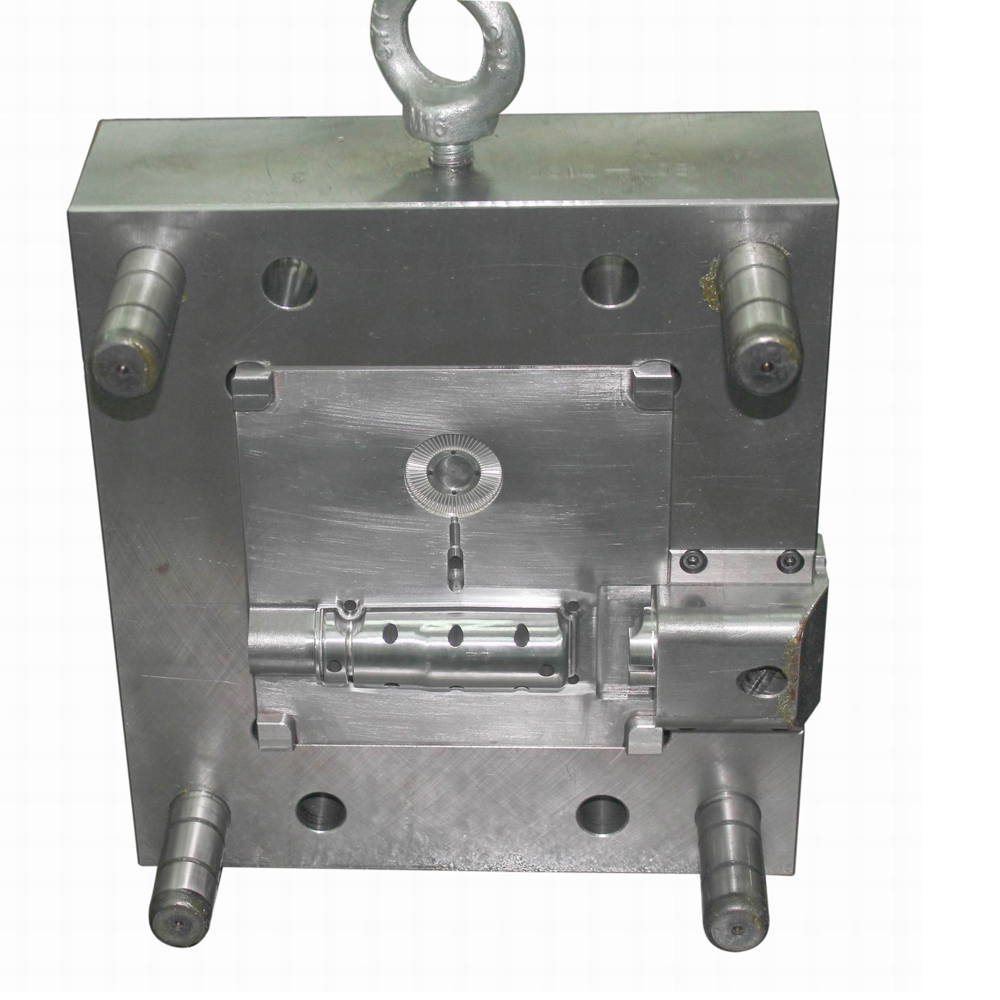

Mould service processing

Injection Mould standard | HASCO,DME,MEUSBURGER,CHINA LKM Standard |

Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

Hardness of steel | 46~56HRC |

Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

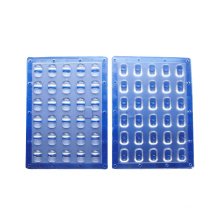

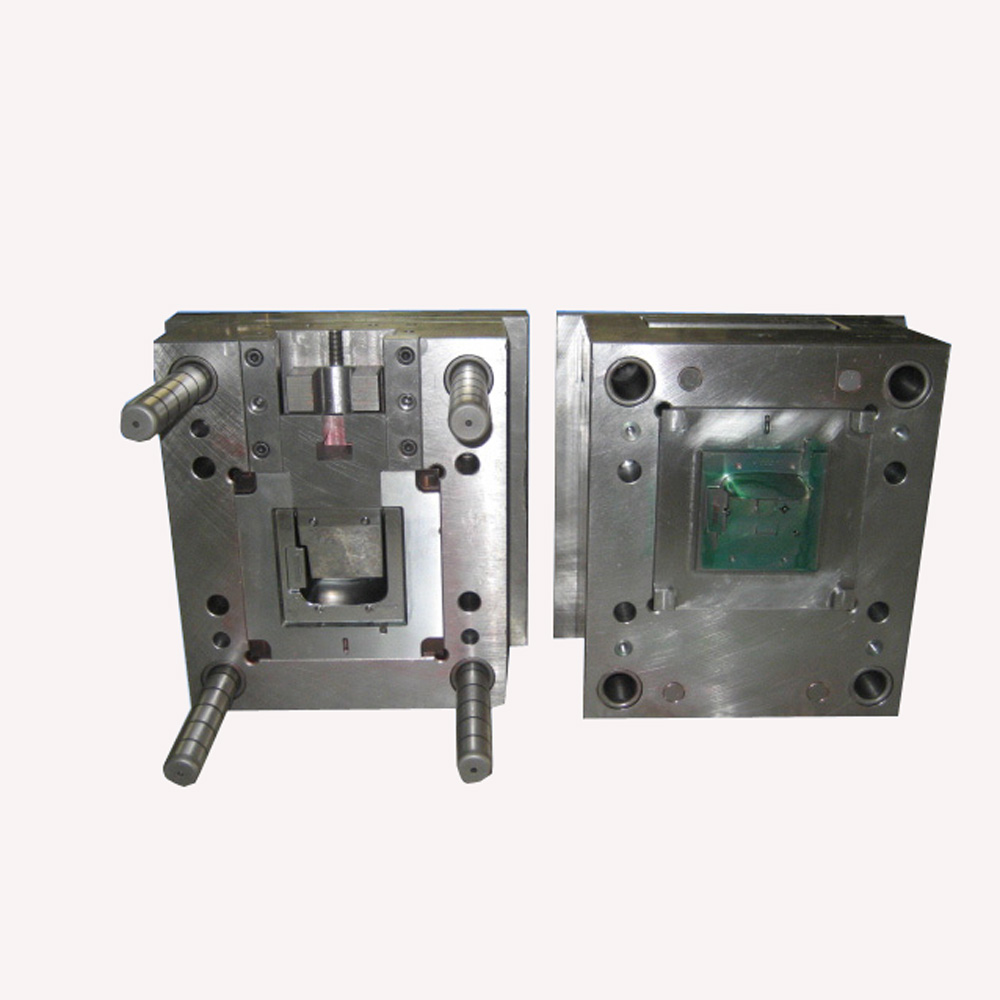

Cavity | Single-cavity ,Multi-cavity |

A surface request: | EDM & High Polish |

Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

Mould life time | 500000~+1,000,000 shots |

Quality | ISO 9001certification |

Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE, PEEK,etc |

Lead time | 4~10 Weeks |

Package | Smoked wooden pallet/Plywood case for tool,PE bags, Carton boxes |

Payment terms | L/C, T/T |

Trade terms | FOB SHENZHEN, EXW |

Export country | Europe countries,USA, Australia ,Middle-east ,Asia etc |

Value-added service | Assembling,Polish,texture,painting,screen printing |

We offer the whole solution of service as following,

1, Part design assistance (with our sugestions you can save the mold cost)

2, Prototype

3, Mold design

4, Mold manufacturing

5, Mold test

6, Mold modification

7, Plastic part injection molding

8, Painting, silk screen, assembly...

9, Packaging and delivery

As a professional supplier for Machining, Injection mold, Die Casting mould & related production maker

Our products mainly support for the following areas:

Electronic: sensor, USB housing, etc

Mobile phone plastic part, remote control, key-press, fingerprint head, handle, cover

Mechanical: Junction box, Motor support part, Pump plastic part

Household: Industrial number calculator part, Juice cup, safety helmet

Medical: hearing aids, Hollow fiber Dialyzer, Blood-Pressure meter, Stapler

Sport: Golf plastic part

Office: Secret code case part, Printer, duplicator, Atom seal

mould package: wooden case or as customer's asked

product color: as customer's requirement

product package: PE bag or foam bag +carton, ect

Why choose us:

1. OEM plastic products manufacturer.

2. Both injection mould making and Plastic Parts producing.

3. Design software: CAD/CAM/CAE, UG, PRO/E

4. Machine: High Speed CNC, Mirror EDM, Sodick WT machine, CMM equipment, etc.

5. Advance: Efficiency with excellent quality.

6. Certificate: ISO9001

7. Continuance service and support.

8. Rich experienced skillful workers.

9. Own custom research and develop department.

Product Categories : Injection Part > Injection Part

Premium Related Products