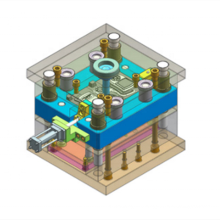

Custom injection molding shell plastic mold injection hearing aid

Product Description

Custom injection molding shell plastic mold injection hearing aid

| Plastical moulding instruction | |

| Mould type | Plastic Injection Mould |

| Mould material | P20 steel, 718,2738,NAK80,S136,2343,2344 etc |

| Mould base | HASCO,DME,MISUMI,JIS,LKM etc |

| Mould runner | HOT runner / Cold runner |

| Mould gate | Slide gate,Sub gate,Hook gate,Pin-point gate |

| Cavity | Single /Multi cavity |

| De-mould type | Auto-ejector |

| Designing software | UG, PROE,CAD |

| Moulding equipment | Lathe,Drill machine,CNC,EDM,Wire-cut machine |

| Lead time | About 3-4 weeks |

| Mould life-circle | 300,000 to 500,000 shot: NAK80,S136,2344 etc; |

| 600,000 shot: P20; | |

| 800,000 shot: 718; | |

| Raw-material | ABS,PP,PC,PA,PA66,PVC,POM etc; |

| Package way | Wooden pallet, carton or as requirement of clinet |

| OEM/ODM | Welcome and please offer 2D/3D file or sample |

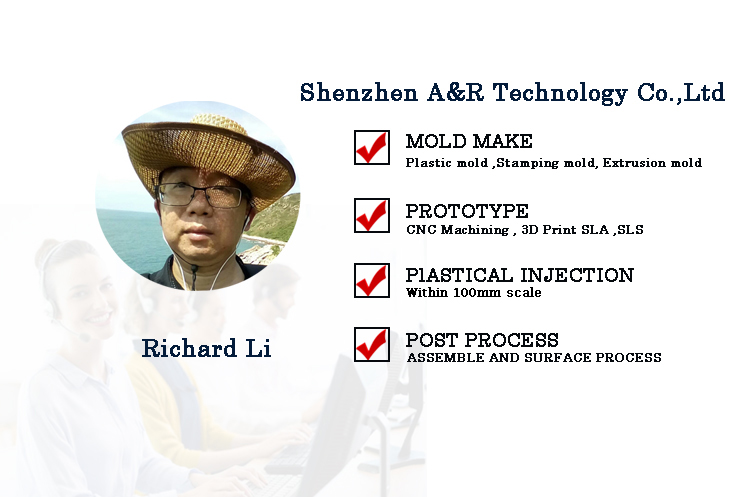

Company introduce

A&R was founded in 2002,still now have been 16 years experience.Company mainly engage in design, molding,Plastic Parts injection and assembling. Our products cover a variety fields that include automotive,electronics,household,toy,medical etc.And 98% products exported to USA, Russia, France,Australia,UK ,South-east country etc,also get greatly praise and agreement.

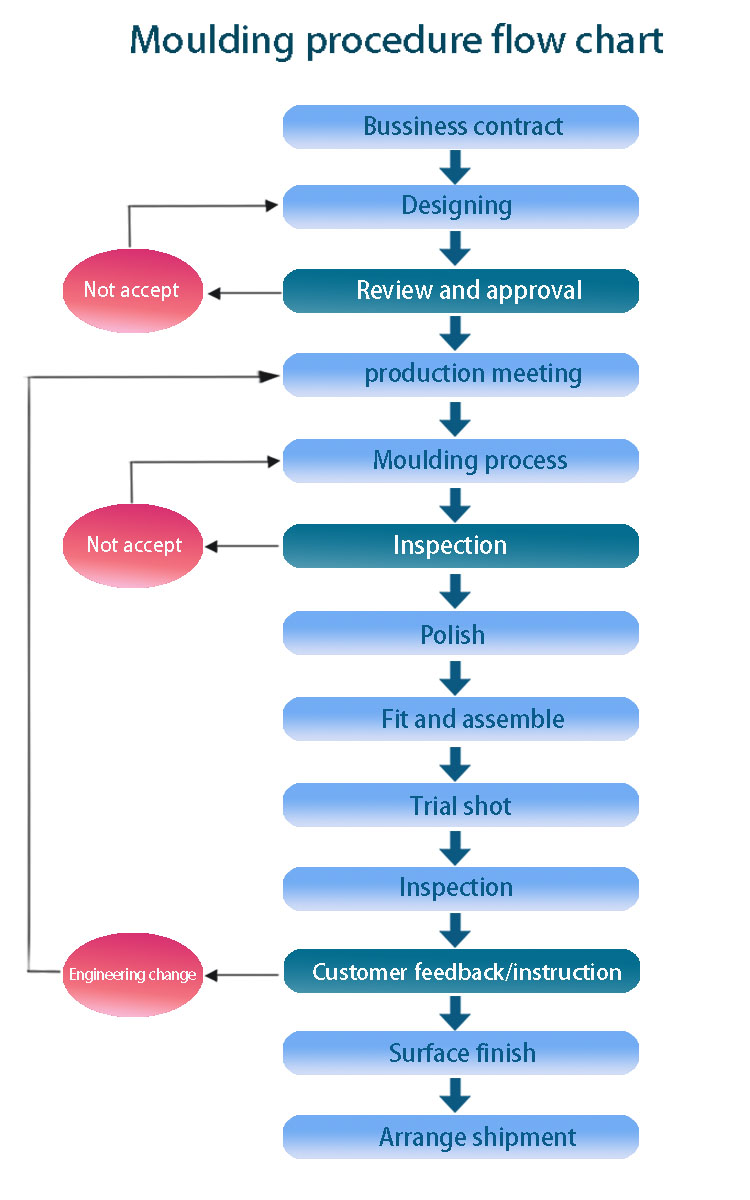

| PRODUCTION PROCEDURE |

OUR SERVICE

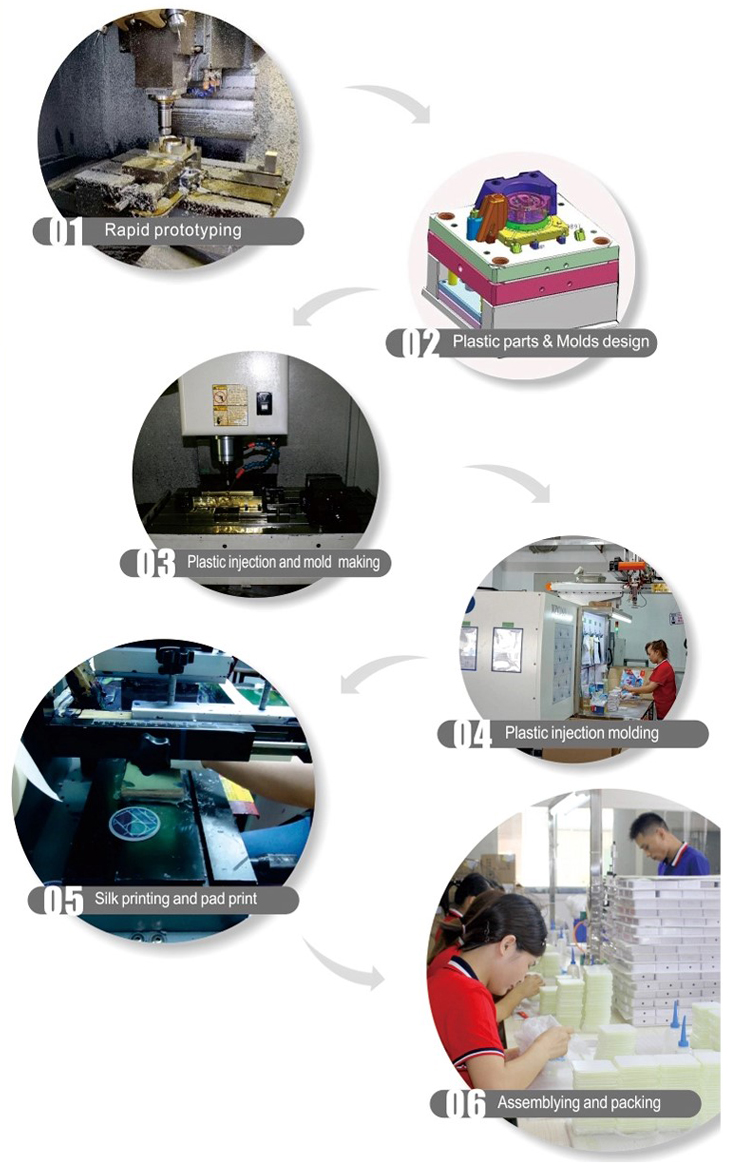

Injection mould and molding,Die Casting mould,metal and plastic prototype,insert and overmolds, multi-cavity mold, hot runner and cold runner injection mould/molding, etc.

| OUR ADVANTAGE |

| CERTIFICATE |

| OUR CUSTOMER |

| Q. I have an idea for a new product,but not sure if it can be manufactured. can you help? |

| A. Yes! We are pleasure to evaluate the technical feasibility of your idea or design, and we can advise on materials, tooling and likely set-up costs. |

| Q.If I want got quotation which type file can i offer? |

| A. Dear, please offer 3D file that include .igs; stl; .step; but .step format is much more appreciated. |

| Q. Which type material is best for my designing product? |

| A. Material selection is mainly depends on your design and application of environment,there are honor and pleasure to offer expertise suggestion,so that suitable material for your project. |

| Q. I've decided to go ahead with my project, how long will i take part? |

| A. It can take 3-5 weeks for mould tool processing,that mainly depend on the part complexity when we received final approval by you,then you could expect delivery within 3 days. |

| Q. What's about your advantage condition? |

| A. We can provide one stop service which from moulding,plastical injection, post processing (such as electroplating,silk surface,polish,paint etc.) so efficient shorten client program lead time that save project innovation cost from conception phase to realization. And we implement 100% inspection during procedure of production to ensurance quality. |

| Q. How about yours business or do you like OEM/ODM? |

| A. We are welcome OEM && ODM.Customer only need provide 3D drawing or sample so that could receive precise quotation.We also have obligation to keep business secret for our client's sale region, designing and Others privacy information. |

Steps

1.Negotiations: Quality,material,price,payment,delivery time item and so on.

2.Place an order: According customers drawing or sample.

3.R&D: According customers requirement design or improve 3D modeling.

4.Design confirmation: We send 3D drawing to customer to confirme.Before we make the mould.

5.Mould processing: CNC EDM machine processing then assembly and trial.

6.Sample confirm: We will send trial sample to customers.Before shipment,If the sample isn’t satisfied customers.We will modify mould until customers satisfaction.

7.Mass production: If customers need mass production plastic products,We can offer.

8.Delivery

Verified Information

The competitive advantage of product line:

Production Capacity:

| Product Line Name | Production Line Capacity | Actual Units Produced(Previous Year) |

|---|---|---|

| Moulds, Plastic Injection Parts | Moulds: 30 Sets/MonthPlastic Injection Parts: 500,000 Pcs/Month | Moulds: 65 SetsPlastic Injection Parts: 3,500,000 Pcs |

Export Market Distribution:

| Market | Revenue(Previous Year) | Total Revenue (%) |

|---|---|---|

| North America | confidential | 4.0 |

| Eastern Europe | confidential | 6.0 |

| Oceania | confidential | 14.0 |

| Western Europe | confidential | 16.0 |

| Domestic Market | confidential | 60.0 |

Real Case for Lower MOQ:

| Products Name | MOQ(in the last 12month) |

|---|---|

| Confidential | confidential |

Real Case for Large Contract:

| Products Name | Order(in the last 12month) |

|---|---|

| Confidential | confidential |

Product Categories : Injection Mould

Premium Related Products