szbergek cnc prototyping services

Basic Info

Model No.: custom

Product Description

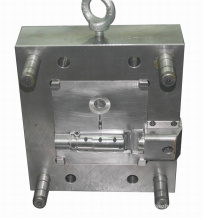

CNC machined parts prototype

There are many reasons for using CNC machining to produce prototypes, including production speed, part quality, material selection, and similarity to the final part.

From files to prototypes

One of the biggest advantages of CNC machining is the "CNC" element. Because CNC machining is the digital process of creating parts from computer files, engineers know that the machined prototype will closely match the digital 3D design and can later use the same digital design to create the final part of the same size. The degree of repeatability is particularly high.

In addition, rapid, precise changes can be made using digital 3D design. If the machined prototype shows physical defects due to poor design, the engineer can go back to CAD software to make appropriate changes for the next prototype. Different versions can be compared side by side, and simulation software can even be used to pre-empt parts' real-world performance.

Quality and consistency

Computers are not perfect, but computer-controlled machines tend to behave as expected unless they crash. While many Prototyping processes rely on human skill (and are therefore vulnerable to human error), CNC machines follow their instructions with less than a millimeter of accuracy.

Importantly, they can also do it over and over again. Although a company may build only one prototype, a CNC machine can run the same job a second time, if needed, with minimal deviation from the first. This is useful for developing new iterations of the prototype and for production using the same machine. (Manual processes are important but easier to ensure consistency with automated machines.)

Strong material range

If the prototype has no mechanical purpose, then it may be suitable for 3D printing, although 3D printing, while not producing high-strength parts, is very cheap and can be done in a short time. For most 3D printing processes, however, the range of material selection is narrower than that of machining.

CNC machining offers not only a wide range of compatible materials but also some very strong and durable materials, including a variety of metals. Metal can also be used for 3D printing, but not with low-cost FDM printers.

Similar to the final section

Another major advantage of CNC machining prototypes is the ability to create prototypes that resemble the final part. Because the machining center is fully capable of producing end-use parts and prototypes, it is possible to create prototypes that come close to the final product -- a feat rarely achieved by 3D printing or other methods.

Part of the problem is materials. Many engineering metals are highly workable, allowing engineers to prototype using the same (or similar) material as the final part. But the quality of the process itself is also a factor: machined parts are strong and do not show weaknesses on certain axes as printed parts do, and the process itself can even be used to replicate other processes, such as sheet metal forming.

In addition, creating a prototype that looks and behaves similar to the final part makes it easier to transition to production because fewer major changes are made.

Contact us if you need more details on Cnc Prototyping Cost Services. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Quality Cnc Prototyping Online、Cnc Prototype Parts Services. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : CNC Machining