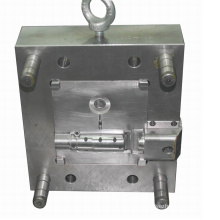

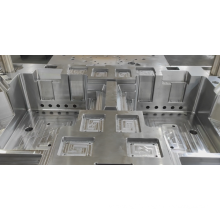

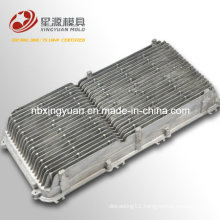

Customized die casting Hanger Bracket

| Payment Type: | T/T |

|---|---|

| Terms of Trade: | FOB,FCA |

| Min. Order: | 1000 Piece/Pieces |

| Delivery Time: | 35 Days |

| Packaging: | carton, pallet |

|---|---|

| Productivity: | 25000/MONTH |

| Brand: | NONE |

| Transportation: | Ocean,Air |

| Place of Origin: | NINGBO |

| Supply Ability: | 90000/MONTH |

| Certificate: | ISO/TS16949:2009 |

| HS Code: | 7616991090 |

| Port: | NINGBO,SHANGHAI |

Basic Info

Model No.: 122

Click on the follow link to find out more information: https://www.bldiecasting.com/agriculture-machinery-parts/

Company Info

- Company Name: NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY

- Representative: LIU CHENGZHI

- Product/Service: Die Casting , Precision Machining , Precision Casting , Pressure Casting , High Precision CNC Machining , Ferrous Metal

- Capital (Million US $): 1000000 RMB

- Year Established: 2001

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 3

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Guisi Industrial Zone, Luotuo Street, Zhenhai District,Ningbo,315206,China

- Contact Person: Mr. Ethan

- Tel: 86-0574-86556929

Email to this supplier

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts