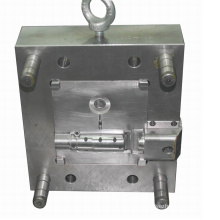

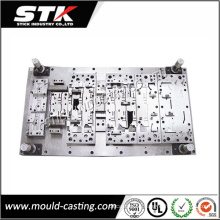

High Pressure Steel Die Casting Mould for Mechanical Parts

Basic Info

Model No.: die casting mould

Product Description

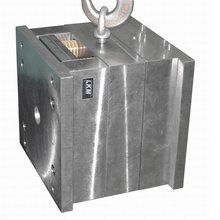

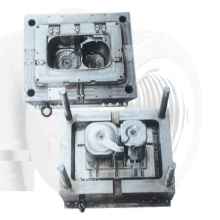

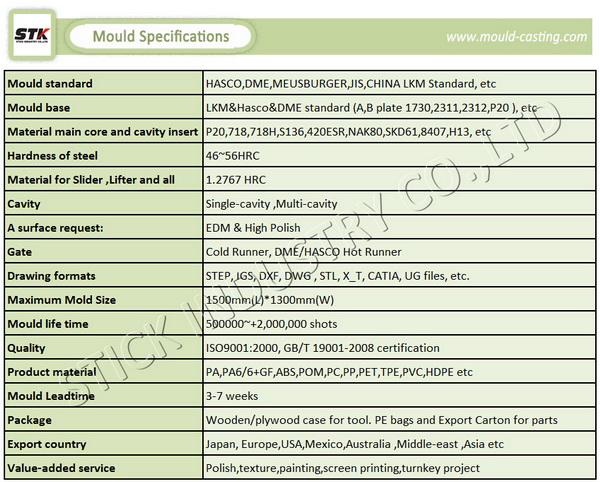

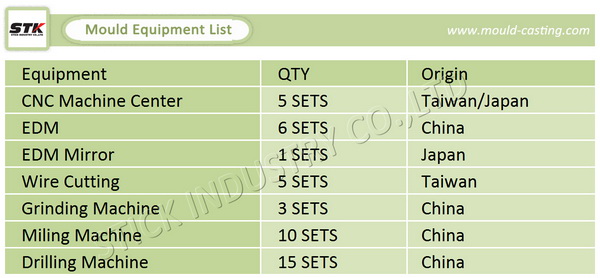

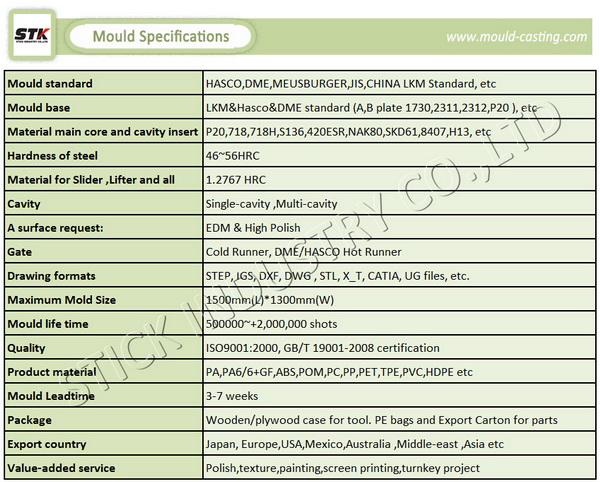

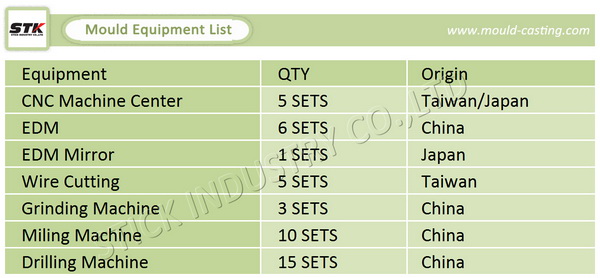

Model NO.: Die Casting mould Material: Steel Surface Treatment: Polished Mould Life: 500,000-1,000,000 shots Material for Die Casting Mold: P20,H13,S136,Nak80,718,2738,2316,SKD61 Drawing: Solidworks, Proe, Ug, Auto CAD, Pdf Delivery Time: 25-30 Days Mold Lifetime: 300k to 1500k Shot Runner: Cold or Hot Runner,Hasco/Dme Trademark: Customized or STK Specification: OEM HS Code: 84807100 Application: Car, Household Appliances, Home Use, Electronic, Hardware, Commodity Demoulding: Slide Using Hardness: >HRC45 Customized: Customized Insert Moulding Material: Zinc,Aluminum,Steel, Brass Shaping Mold: Die Casting Mold Mould Range: 20-25t Cavity: 1*1,1+1,1*2,1+1+1 Zinc Die Casting Machine: 80t-280t Transport Package: Wooded Box for Mould Origin: China 1) Mould Standard: HASCO, JIS, DME etc

2) Core material: H13, 8407 etc

3) Cavity: single or multiple (1*1,1+1,1*2,1+1+1)

4) Hardness of steel: 40-60 HRC

5) Lead time: 3-6 weeks depending on products

6) Product Material: Aluminum alloy, Zinc alloy

7) Suitable for both cold chamber and hot chamber machines

8) Machine Size: Zinc Die Casting Machine: 80T-280T; Aluminum Die Casting Machine: 200T-650T

Contact us if you need more details on Mechanical Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Die Casting Mold、Die Casting Moulding. If these products fail to match your need, please contact us and we would like to provide relevant information.

2) Core material: H13, 8407 etc

3) Cavity: single or multiple (1*1,1+1,1*2,1+1+1)

4) Hardness of steel: 40-60 HRC

5) Lead time: 3-6 weeks depending on products

6) Product Material: Aluminum alloy, Zinc alloy

7) Suitable for both cold chamber and hot chamber machines

8) Machine Size: Zinc Die Casting Machine: 80T-280T; Aluminum Die Casting Machine: 200T-650T

| Why choose us? | Xiamen Stick Industry began in the mold manufacturing industry in 2002, and our company has grown steadily since then. We have an experienced and dedicated team that supports all aspects of rapid mold manufacturing and plastic injection mold design. l In-house mold design and mold manufacturing l Precision single and multi-cavity molds l Rapid prototype to high volume molds l Design for manufacturability l Fast turnaround |

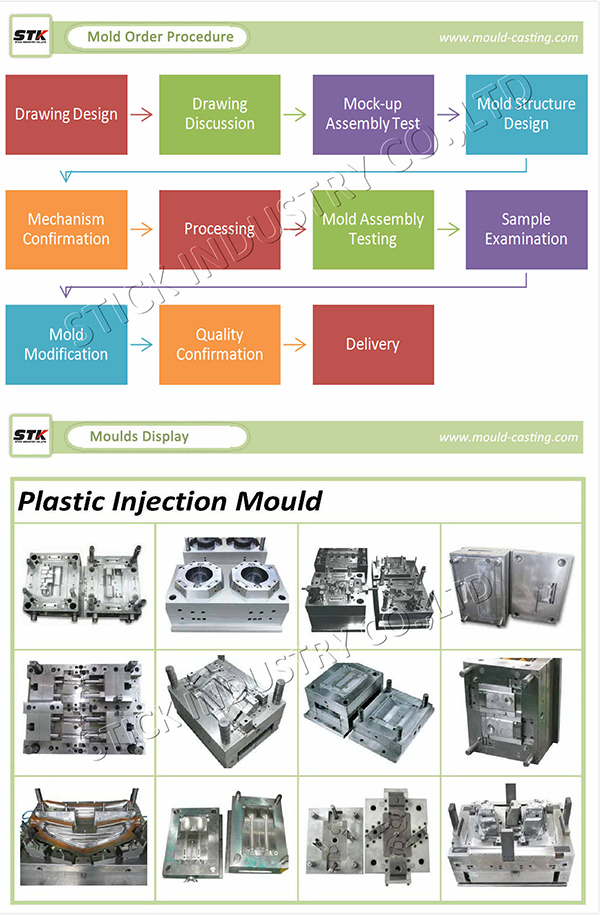

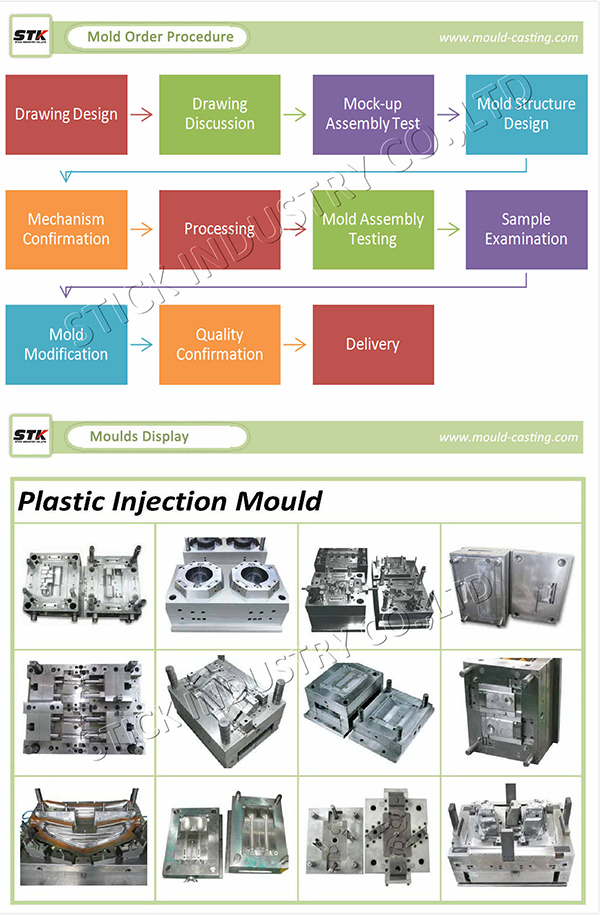

| Flow Chart | 1. Drawing design |

| 2. Drawing discussion | |

| 3. Mock-up assembly testing | |

| 4. Mold structure design | |

| 5. Mechanism confirmation | |

| 6. Processing | |

| 7. Mold assembly testing | |

| 8. Sample examination | |

| 9. Mold modification | |

| 10. Quality confirmation | |

| 11. Delivery | |

| Material utilized in mould design | P20, H13, S136, NAK80, 718, 2738, 2316, SKD61, etc Tool steel or beryllium-copper are often used. Mild steel or aluminum is only suitable for very short production runs. |

Product Categories : 4) Moulds

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts