OEM Mold Making, 800000 Shots, Plastic Injection Mould

Basic Info

Model No.: STK-M-24

Product Description

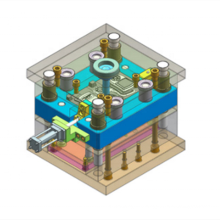

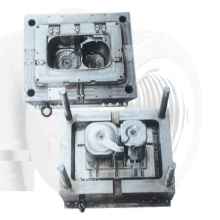

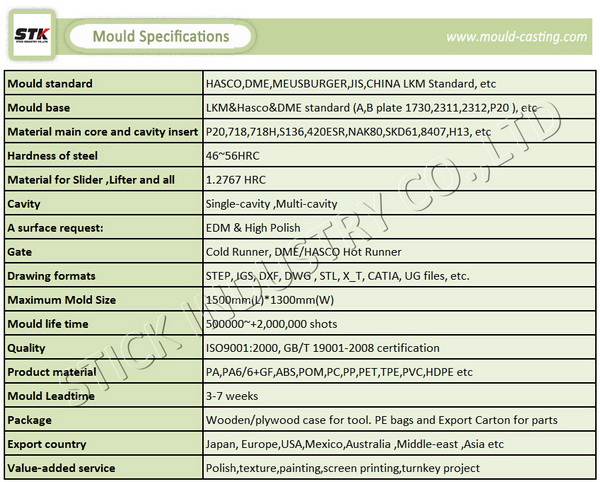

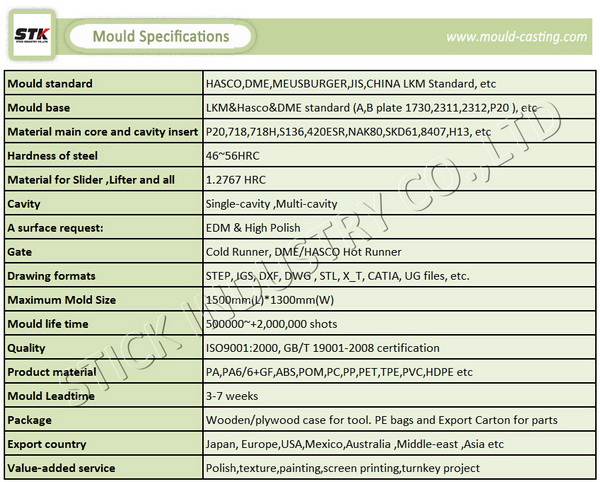

Model NO.: STK-M-24 Process Combination Type: Single-Process Mode Installation: Fixed Mould Steel: #45, #50, P20, H13, 718, 2738, Nak80, S136 etc Machine Size: 80tons-1600tons Trademark: STK or customerized Specification: ISO 9001: 2000 HS Code: 8480710090 Shaping Mode: Injection Mould Application: Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Core and Cavity Material: 718, 718h, Nak80, P20, SKD61 etc Mould Life: 800000 Shots Mold Base: Lkm,Futa, Hasco, Dme, etc Transport Package: Wooden Case for Mould, Carton for Plastic Part Origin: Xiamen, Fujian, China Specifications

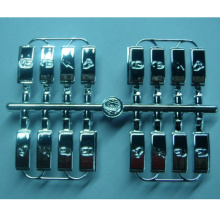

1. Mould Cavity: Single to more than 10 cavities

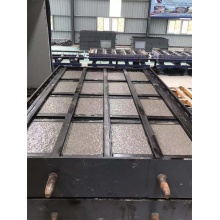

2. Runner: Cold or Hot

3. Mould life: 500000-1000000 shots

4. Material: Steel, steel alloy such as P20, 8074, 2083 or NAK-55

5. Mould base: LKM, FUTA, HASCO, DME, etc.

6. Production Leadtime: 3-6 weeks depending on the complexity of drawings.

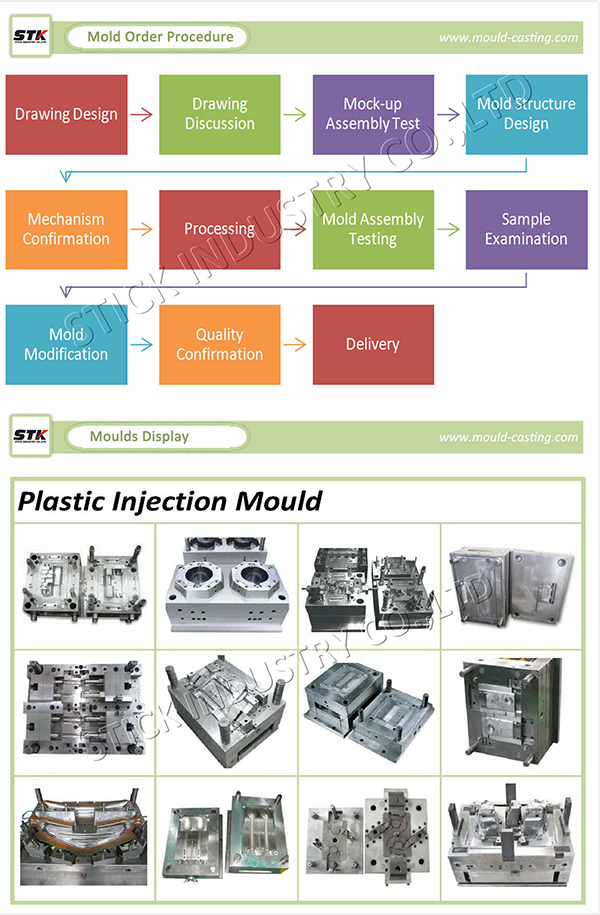

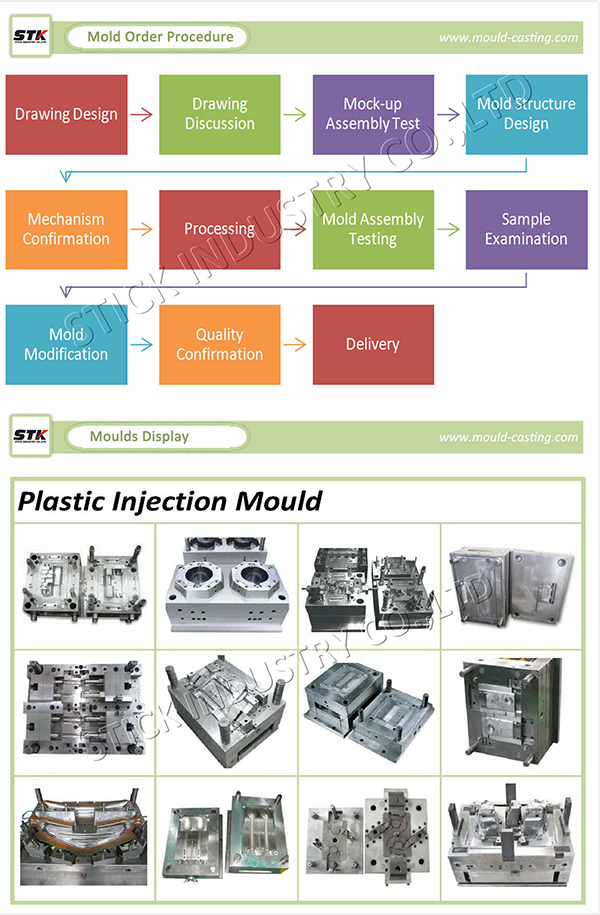

Flow Chart

1. Drawing design

2. Drawing discussion

3. Mock-up assembly testing

4. Mold structure design

5. Mechanism confirmation

6. Processing

7. Mold assembly testing

8. Sample examination

9. Mold modification

10. Quality confirmation

11. Delivery

Contact us if you need more details on Plastic Injection Mold. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 800000 Shots、#45 #50 P20 H13 718 2738 Nak80 S1. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Mould Cavity: Single to more than 10 cavities

2. Runner: Cold or Hot

3. Mould life: 500000-1000000 shots

4. Material: Steel, steel alloy such as P20, 8074, 2083 or NAK-55

5. Mould base: LKM, FUTA, HASCO, DME, etc.

6. Production Leadtime: 3-6 weeks depending on the complexity of drawings.

Flow Chart

1. Drawing design

2. Drawing discussion

3. Mock-up assembly testing

4. Mold structure design

5. Mechanism confirmation

6. Processing

7. Mold assembly testing

8. Sample examination

9. Mold modification

10. Quality confirmation

11. Delivery

| Company Advantage | (1) Auto Parts high precision injection mould; (2)Strictly obeys the processing procedure according to customer' s requirements; (3) Fast delivery of T1 samples. (4) In-house inejction mould designing available; |

| Core and Cavity Material: | 718, 718H, S136, NAK80, P20, SKD61 etc. |

| Plastic Material: | ABS, PP, PE, PET, EVA, PMMA, PC, PU etc. |

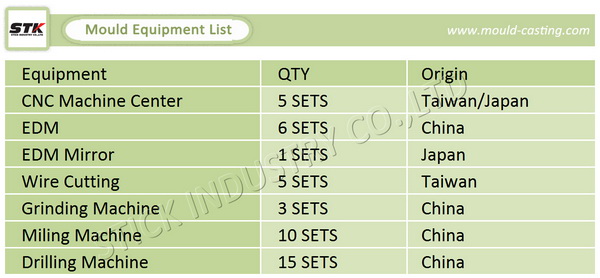

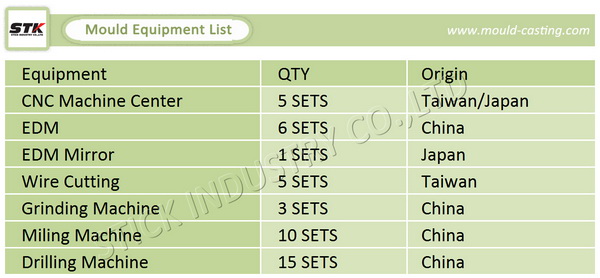

| Main Processing Equipment | CNC, Grinding machine, Lathe, Drill Press, EDM center |

| Practicable Software: | Pro/engineer, Solidworks, UG, Auto cad. |

| Business Scope: | 1, Industrial design 2, Mould making 3, Parts machining 4, Reverse engineering 5, Injection molding 6, CNC prototype manufacturing |

Product Categories : 4) Moulds

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts