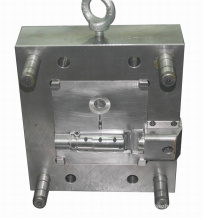

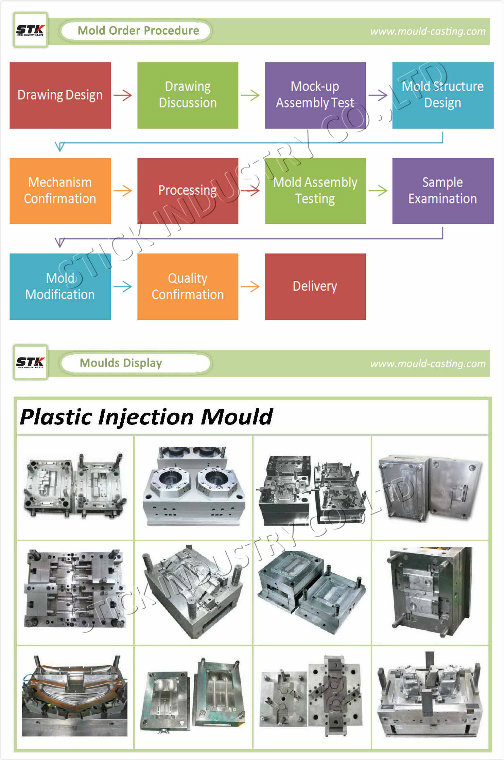

Plastic Injection Mould for Plastic Parts

Basic Info

Model No.: STK-M-1102

Product Description

Mold Standard | HASCO, DME, JIS, CHINA LKM |

Mold Base | LKM & HASCO & DME standard |

Material Main Core & Cavity Insert | P20, 718, 718H, S136, 420ESR, NAK80, SKD61, 8407, H13 |

Hardness of Steel | 46~56HRC |

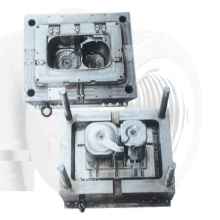

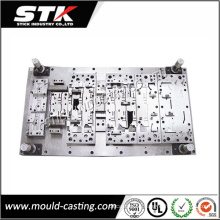

Cavity | Single-cavity, Multi-cavity |

Surface Finish | EDM & High Polish |

Gate | Cold Runner, DME/HASCO Hot Runner |

Maximum Mold Size | 1500mm(L)*1300mm(W) |

Mold Life Time | 50,000shots ~ +1,000,000shots |

Applied Software | Pro-E, Solid Works, UG, CAD |

Quality | ISO9001-2000 Certification |

Product Material | PA, PA6/6+GF, ABS, POM, PC, PP, PET, TPE, PVC, HDPE etc |

Lead-time | 4-7 weeks |

Package | Wooden/plywood case for tool. PE bags and Export Carton for parts |

Export Country | Europe, The US, Mexico, Russia, Australia, Middle-East, Asia etc |

Value-added Service | Polish, Texture, Painting, Screen-Printing |

Advantage: u In-house mold design and mold manufacturing u Precision Single-cavity and multi-cavity molds u Design for Manufacturability u Fast Turnaround

Advantage: u In-house mold design and mold manufacturing u Precision Single-cavity and multi-cavity molds u Design for Manufacturability u Fast Turnaround Ms Ivy Lo

Ms Ivy LoXIAMEN STICK INDUSTRY CO., LTD

Unit 05C,5th Floor,Hai Fu Business Center,

A 597 Shi Shui Road,Xiamen,China. Post Code:361008

Pho: (86)592-5209671, Fax: (86)592-5209672

Web: www.stickindustry.com www.mold-custom.com Contact us if you need more details on Plastic Mould of Injection. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Mould、Plastic Mold. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : 4) Moulds

Premium Related Products