OEM Custom Plastic Injection Mobile Phone Shell, Mobile Cover (STK-ZDO0010)

Basic Info

Model No.: STK-ZDO0010

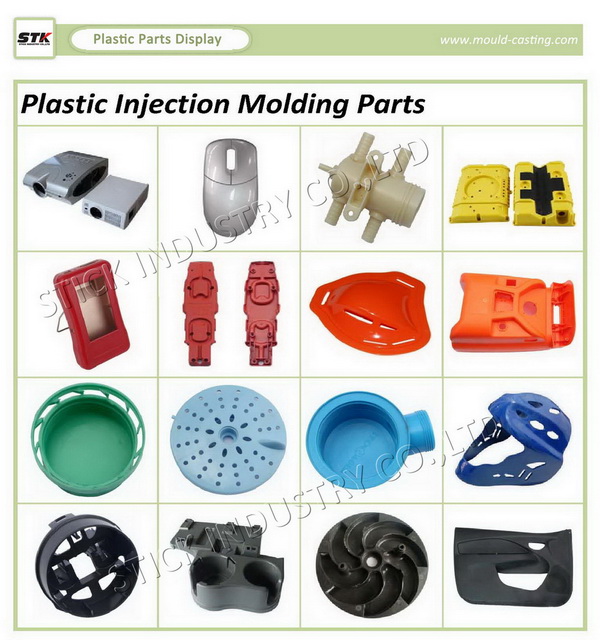

Product Description

Model NO.: STK-ZDO0010 Surface Finish Process: Painting Plastic Material: Plastic Application: Household Appliances, Electronic, Home Use Design Software: AutoCAD Certification: CE, ISO, SGS Customized: Customized Surface Finish: Powder Coating, Silk-Printing, Laser Etching, etc Software Applied: PRO/E, Autocad 2000, Solidwork 2001 Usage: Auto Parts, Medical Appliance, Electronies Material: PP, ABS, POM, Nylon, PC Delivery Time: 2-4weeks Transport Package: Standard Export Package Origin: China Shaping Mode: Injection Mould Mould Cavity: Single Cavity Process Combination Type: Single-Process Mode Runner: Hot Runner Installation: Fixed Standard: HASCO Certificate: ISO9001:2000 Brand: Customed and OEM Applications: Electronics, Audio Parts, Acoustic Parts Machine: 80 Ton to 800 Ton Process: Plastic Injection Molding Trademark: Customized or STK Specification: ISO 9001: 2000 HS Code: 39252000 Plastic Injection Molding Shells and Cover for Mobile Phone

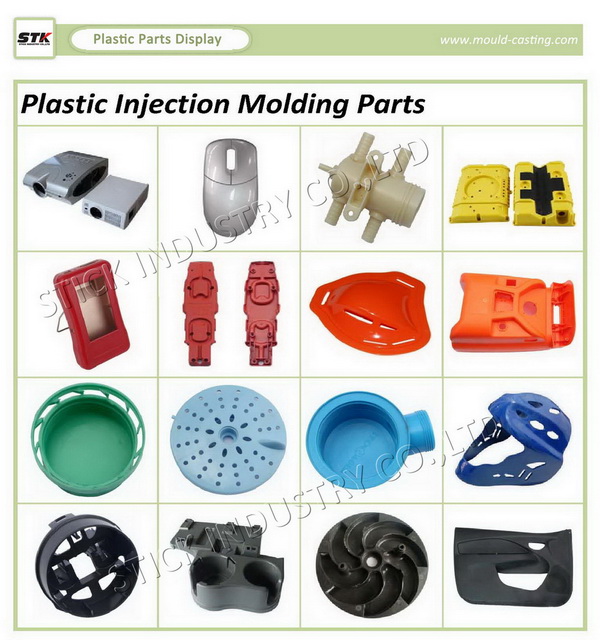

Plastic Injection Solution:

u Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class production

u Parts are widely used: Industrial, Automotive, Electronics & Medical

Technical Skills - Development, Design Skills

l Design Consultation & Assistance

l Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysis

l Material Selection Assistance

l Quick turn-around prototype support

l Secondary Operations including machining, welding & assembly

Molding - High Precision, High Concern

l Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stamping

l 40 Molding machines from 80TONS to 1400TONS

l High precision molding from medical to fiber optics components

Secondary Operations - Value Added Service

l Pad Printing

l Sonic Welding

l Assembly & Packaging

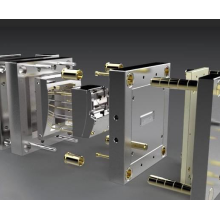

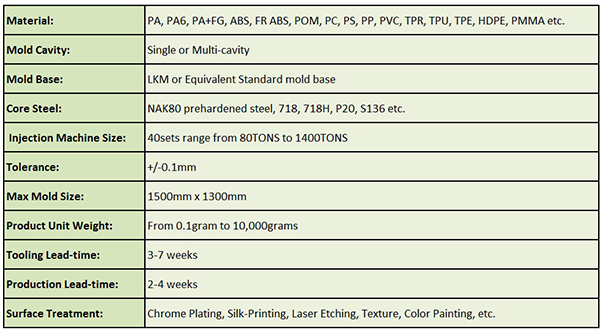

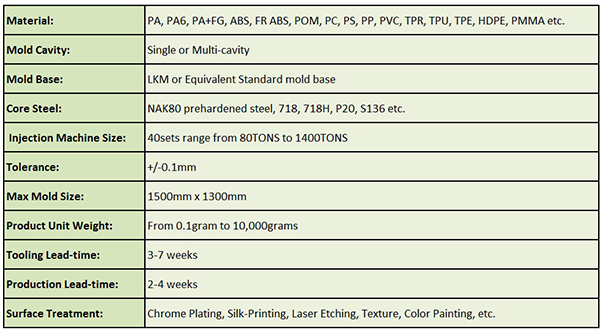

Injection Molding Capability

u Material: PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc.

u Mold Cavity: Single or Multi-cavity

u Mold Base: LKM or Equivalent Standard mold base

u Core Steel: NAK80 prehardened steel, 718, 718H, P20, S136 etc.

u Injection Machine Size: 40sets range from 80TONS to 1400TONS

u Max Mold Size: 1500mm x 1300mm

u Product Unit Weight: From 0.1gram to 10,000grams

u Tooling Lead-time: 3-7 weeks

u Production Lead-time: 2-4 weeks

u Mold Life: 50,000shots to 500,000shots

u Surface Treatment: Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.

Injection Molding Capability

u Material: PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc.

u Mold Cavity: Single or Multi-cavity

u Mold Base: LKM or Equivalent Standard mold base

u Core Steel: NAK80 prehardened steel, 718, 718H, P20, S136 etc.

u Injection Machine Size: 40sets range from 80TONS to 1400TONS

u Max Mold Size: 1500mm x 1300mm

u Product Unit Weight: From 0.1gram to 10,000grams

u Tooling Lead-time: 3-4 weeks

u Production Lead-time: 2-4 weeks

u Mold Life: 50,000shots to 500,000shots

u Surface Treatment: Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.

Ms Ivy Lo

XIAMEN STICK INDUSTRY CO., LTD

Unit 05C,5th Floor,Hai Fu Business Center,

A 597 Shi Shui Road,Xiamen,China. Post Code:361008

Pho: (86)592-5209671, Fax: (86)592-5209672

Web: www.stickindustry.com www.mold-custom.com Contact us if you need more details on Mobile Phone Cover. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Injection Mould、Plastic Injection Cover. If these products fail to match your need, please contact us and we would like to provide relevant information.

Plastic Injection Solution:

u Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class production

u Parts are widely used: Industrial, Automotive, Electronics & Medical

Technical Skills - Development, Design Skills

l Design Consultation & Assistance

l Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysis

l Material Selection Assistance

l Quick turn-around prototype support

l Secondary Operations including machining, welding & assembly

Molding - High Precision, High Concern

l Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stamping

l 40 Molding machines from 80TONS to 1400TONS

l High precision molding from medical to fiber optics components

Secondary Operations - Value Added Service

l Pad Printing

l Sonic Welding

l Assembly & Packaging

Injection Molding Capability

u Material: PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc.

u Mold Cavity: Single or Multi-cavity

u Mold Base: LKM or Equivalent Standard mold base

u Core Steel: NAK80 prehardened steel, 718, 718H, P20, S136 etc.

u Injection Machine Size: 40sets range from 80TONS to 1400TONS

u Max Mold Size: 1500mm x 1300mm

u Product Unit Weight: From 0.1gram to 10,000grams

u Tooling Lead-time: 3-7 weeks

u Production Lead-time: 2-4 weeks

u Mold Life: 50,000shots to 500,000shots

u Surface Treatment: Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.

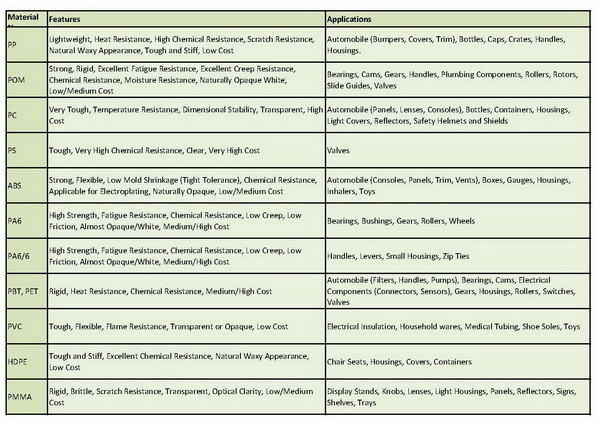

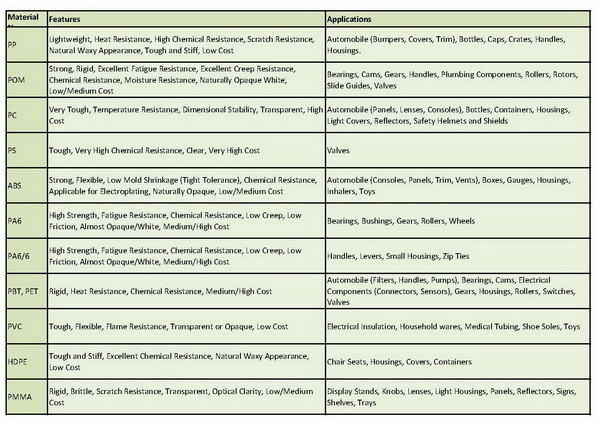

| Material Name | Features | Applications |

| PP | Lightweight, Heat Resistance, High Chemical Resistance, Scratch Resistance, Natural Waxy Appearance, Tough and Stiff, Low Cost | Automobile (Bumpers, Covers, Trim), Bottles, Caps, Crates, Handles, Housings. |

| POM | Strong, Rigid, Excellent Fatigue Resistance, Excellent Creep Resistance, Chemical Resistance, Moisture Resistance, Naturally Opaque White, Low/Medium Cost | Bearings, Cams, Gears, Handles, Plumbing Components, Rollers, Rotors, Slide Guides, Valves |

| PC | Very Tough, Temperature Resistance, Dimensional Stability, Transparent, High Cost | Automobile (Panels, Lenses, Consoles), Bottles, Containers, Housings, Light Covers, Reflectors, Safety Helmets and Shields |

| PS | Tough, Very High Chemical Resistance, Clear, Very High Cost | Valves |

| ABS | Strong, Flexible, Low Mold Shrinkage (Tight Tolerance), Chemical Resistance, Applicable for Electroplating, Naturally Opaque, Low/Medium Cost | Automobile (Consoles, Panels, Trim, Vents), Boxes, Gauges, Housings, Inhalers, Toys |

| PA6 | High Strength, Fatigue Resistance, Chemical Resistance, Low Creep, Low Friction, Almost Opaque/White, Medium/High Cost | Bearings, Bushings, Gears, Rollers, Wheels |

| PA6/6 | High Strength, Fatigue Resistance, Chemical Resistance, Low Creep, Low Friction, Almost Opaque/White, Medium/High Cost | Handles, Levers, Small Housings, Zip Ties |

| PBT, PET | Rigid, Heat Resistance, Chemical Resistance, Medium/High Cost | Automobile (Filters, Handles, Pumps), Bearings, Cams, Electrical Components (Connectors, Sensors), Gears, Housings, Rollers, Switches, Valves |

| PVC | Tough, Flexible, Flame Resistance, Transparent or Opaque, Low Cost | Electrical Insulation, Household wares, Medical Tubing, Shoe Soles, Toys |

| HDPE | Tough and Stiff, Excellent Chemical Resistance, Natural Waxy Appearance, Low Cost | Chair Seats, Housings, Covers, Containers |

| PMMA | Rigid, Brittle, Scratch Resistance, Transparent, Optical Clarity, Low/Medium Cost | Display Stands, Knobs, Lenses, Light Housings, Panels, Reflectors, Signs, Shelves, Trays |

Injection Molding Capability

u Material: PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc.

u Mold Cavity: Single or Multi-cavity

u Mold Base: LKM or Equivalent Standard mold base

u Core Steel: NAK80 prehardened steel, 718, 718H, P20, S136 etc.

u Injection Machine Size: 40sets range from 80TONS to 1400TONS

u Max Mold Size: 1500mm x 1300mm

u Product Unit Weight: From 0.1gram to 10,000grams

u Tooling Lead-time: 3-4 weeks

u Production Lead-time: 2-4 weeks

u Mold Life: 50,000shots to 500,000shots

u Surface Treatment: Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.

Ms Ivy Lo

XIAMEN STICK INDUSTRY CO., LTD

Unit 05C,5th Floor,Hai Fu Business Center,

A 597 Shi Shui Road,Xiamen,China. Post Code:361008

Pho: (86)592-5209671, Fax: (86)592-5209672

Web: www.stickindustry.com www.mold-custom.com Contact us if you need more details on Mobile Phone Cover. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Injection Mould、Plastic Injection Cover. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : 3) Plastic Injection Parts

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts