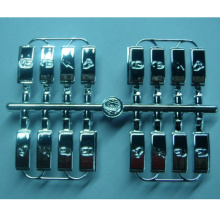

ABS Mobile Phone Case for Electronic Accessories (STK-MP-0421)

Basic Info

Model No.: STK-MP-0421

Product Description

Model NO.: STK-MP-0421 Type: Case Style: Simplicity Function: Dirt-resistant, Decoration Car Holder: Without Car Holder Certification: ISO9001 Usage: Case, Housing, Cover, Shell Place of Origin: China Specification: ISO 9001: 2000, SGS HS Code: 3926909090 Compatible Brand: Customized Gender: Unisex Material: Plastic Color: Customized Hardness: Partial Hard Market Served: Electronics (Mobile Phone) Export Markets: Global Trademark: Customized or STK Origin: China Our Service:

1. More than 20 years plastic injection molding experience.

2. Shaping mode: Plastic injection molding.

3. Style: Any style as your demand.

4. Delivery time: 25-30 days for mould and 10 days for production.

5. Material: Range from PP, PC, PS, PE, POM, PLA, ABS.

6. One-stop solution: Both pplastic product and mould are avaiable.

7. Design Consultation and Assistance

8. CAD/CAM/CAE including Solid Works (TM) and mold flow analysis

9. Material Selection Assistance

10. Domestic and Foreign Tooling Sources

11. Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing and hot stamping

12. Secondary Operations including machining, welding and assembly

13. Zero-defect tool DFM approach

14. Quick turn-around prototype support

Plastic Injection Solution:

1. Broad-based expertise, full-service capabilities and a track record for solving complex challenges sets Xiamen Stick Industry in a highly competitive marketplace.

2. We provide services to help with product design, material selection, and CAD/CAM/CAE capabilities including Solid Works (TM) and mold flow analysis along with product assembly, decorating and plastic welding.

3. Our main production area is equipped with 27 moulding machines of various sizes, ranging from 15 tonne to 320 tonne clamping pressure. This provides us with the capability to mould shot weights from 0.1 gram to over 750 grams with flexible production runs.

Contact us if you need more details on Phone Case. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Phone Housing、Mobile Phone Case. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. More than 20 years plastic injection molding experience.

2. Shaping mode: Plastic injection molding.

3. Style: Any style as your demand.

4. Delivery time: 25-30 days for mould and 10 days for production.

5. Material: Range from PP, PC, PS, PE, POM, PLA, ABS.

6. One-stop solution: Both pplastic product and mould are avaiable.

7. Design Consultation and Assistance

8. CAD/CAM/CAE including Solid Works (TM) and mold flow analysis

9. Material Selection Assistance

10. Domestic and Foreign Tooling Sources

11. Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing and hot stamping

12. Secondary Operations including machining, welding and assembly

13. Zero-defect tool DFM approach

14. Quick turn-around prototype support

Plastic Injection Solution:

1. Broad-based expertise, full-service capabilities and a track record for solving complex challenges sets Xiamen Stick Industry in a highly competitive marketplace.

2. We provide services to help with product design, material selection, and CAD/CAM/CAE capabilities including Solid Works (TM) and mold flow analysis along with product assembly, decorating and plastic welding.

3. Our main production area is equipped with 27 moulding machines of various sizes, ranging from 15 tonne to 320 tonne clamping pressure. This provides us with the capability to mould shot weights from 0.1 gram to over 750 grams with flexible production runs.

| Item name | ABS plastic case |

| Company profile | We are one of leading ISO 9001: 2000 certified manufacturer of mold design and fabrication that include plastic molds, plastic injection parts and plastic injection molding in china. |

| Product description | 1. Cavity: single or multi-cavities 2. Injection Material: ABS, flame-resistant ABS, PC, PC/ABS, PS, PP, PVC, TPR, TPU, HDPE, PMMA 3. Surface Finish: Chrome Plating, silk-printing, Laser etching, texture, color painting and more are available 4. Mould Leadtime: 20-30 days depending on the size of the products 5. Production Leadtime: 15-30 days depending on the quantity of the order 6. Injection Maching Size: 20 sets range from 120T to 850T 7. Max. Mould Size: 1700x1700mm 8. Max. Product Size: 1200x1200mm |

| Advantage | 1. Our factory is specialized in doing OEM/ODM products according to customers drawings or samples 2. Software for specification drawings: Pro/E, Auto CAD, solid work 2001, CAXA, UG, CAD, CAM 3. Certificates: ISO 9001: 2000 4. Advanced equipment, excellent R& D teams and strict quality control system |

Contact us if you need more details on Phone Case. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Phone Housing、Mobile Phone Case. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : 3) Plastic Injection Parts

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts