OEM & ODM Custom Precision Machined Aluminum Alloy Die Cast Components

Basic Info

Model No.: STK-ADO0026

Product Description

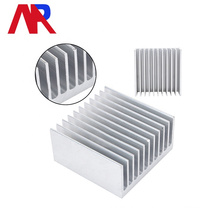

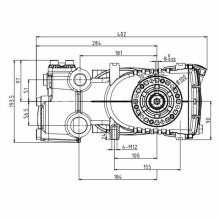

Model NO.: STK-ADO0026 Die Casting Method: Precision Die Casting Machining: Machining Center Surface Preparation: Raw Finish Tolerance Grade: 4 Certification: SGS, ISO 9001:2000 Machine Size: 25-800 Tons Material Available: ADC10, ADC12, A380, 383,B390 (Yl117), Yl112, Yl104 Surface Treatment: Short Blasting, Powder Coating, Chrome Plating etc Software Applied: PRO/E, Auto CAD 2000, Solid Work 2001, Caxa, Ug, C Port of Loading: Xiamen Port Transport Package: Foam Bag+Export Carton Origin: Xiamen, China Die Casting Machine Type: Cold Chamber Die Casting Machine Application: LED Lighting Material: Aluminum Alloy Pressure Chamber Structure: Horizontal Casting Surface Quality Level: 2 Weight Available: 0.02 Kg to 10 Kgs Process: Cold Chamber Die Casting Lead-Time: 2-4 Weeks Services: Casting, Machining, Fabrication, Stamping etc Markets: Global Trademark: STK or Customized Specification: ISO 9001: 2000, SGS HS Code: 76169090 Xiamen Stick Industry Co., Ltd.are a professional die cast and injection molding manufacturer in China,specializing in producing Moulds, plastic injection molding, Aluminum/Zinc Die casting, CNC Machining, Sheet Metal Forming, Surface Treatments, Assembly for your OEM order with competitive price

We are one of leading ISO 9001: 2000 certified manufacturer of stamping, punching, welding, threading, sheet metal cutting, deep draw and bending in China. Our products vary from home appliances, office appliances, precise automotive industries, to spare parts of industry hardware and etc

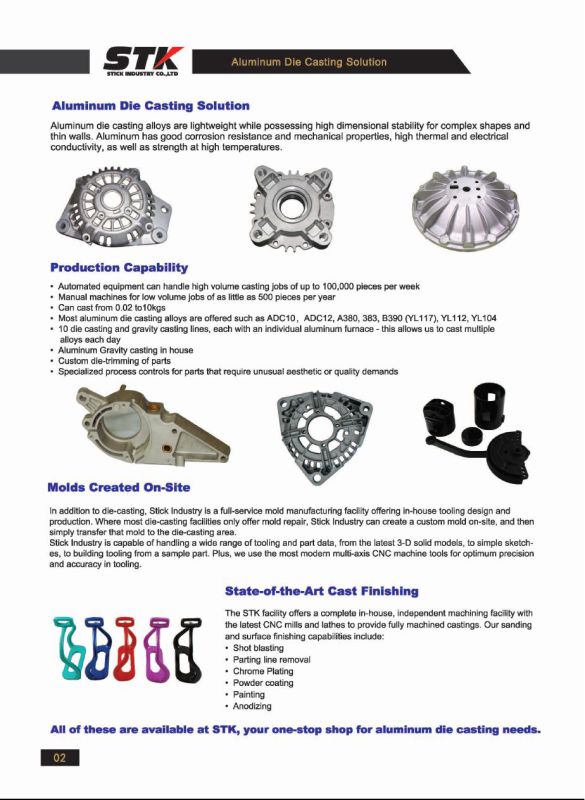

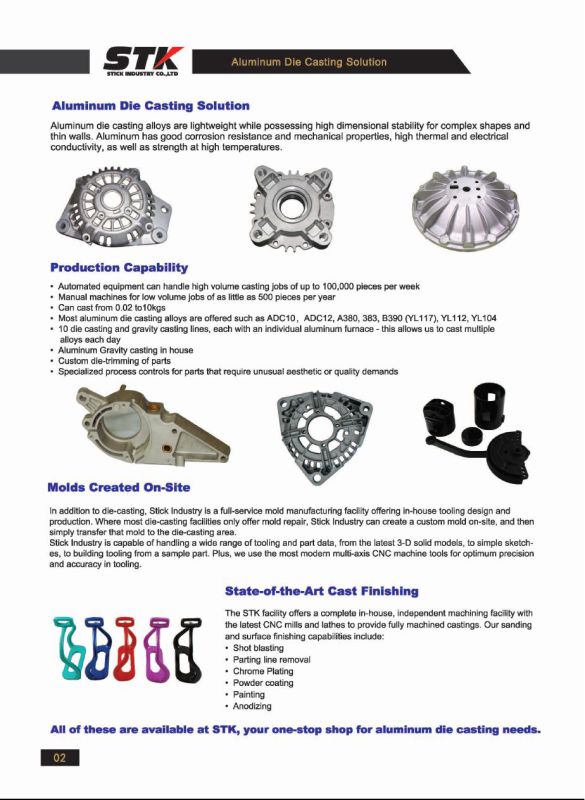

Aluminum Die Casting Alloys:

u Lightweight

u High dimensional stability for complex shapes & thin walls

u Good Corrosion Resistance & Mechanical Properties

u High Thermal & Electrical Conductivity

u High Strength at High Temperatures

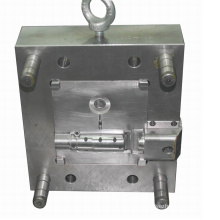

At STK, all Aluminum die casting tooling is designed and built in-house to meet both the customer's and STK's own exacting standards. Production processes for each project are carefully planned, documented and monitored utilizing various statistical process control techniques.

Production Capabilities:

Automated equipment can handle high volume casting jobs of up to 100,000 pieces per week

Manual machines for low volume jobs of as little as 500 pieces per year

Can cast from 0.02 to 10kgs

Single to Multiple Cavities

Most Aluminum die casting alloys are offered such as ADC10, ADC12, A380, 383, B390 (YL117), YL112, YL104

10 die casting & gravity casting lines. Each with an individual aluminum furnace which allows us to cast multiple alloys

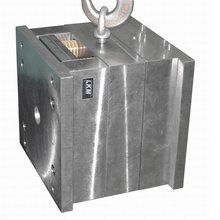

7 sets of Cold Chamber Die Casting Machines. Range from 125 Tons to 800 Tons. And 3 sets of Gravity Machines.

We will pay great attention to your any question or enquiry.

If any questions, please feel free to contact us at any time.

Tel: 86-592- 5209671

Fax: 86-592- 5209672

Ms.Anna Lin

Website:www.stickindustry.com / www.mould-casting.com Contact us if you need more details on Aluminum Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Die Casting、Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

We are one of leading ISO 9001: 2000 certified manufacturer of stamping, punching, welding, threading, sheet metal cutting, deep draw and bending in China. Our products vary from home appliances, office appliances, precise automotive industries, to spare parts of industry hardware and etc

Aluminum Die Casting Alloys:

u Lightweight

u High dimensional stability for complex shapes & thin walls

u Good Corrosion Resistance & Mechanical Properties

u High Thermal & Electrical Conductivity

u High Strength at High Temperatures

At STK, all Aluminum die casting tooling is designed and built in-house to meet both the customer's and STK's own exacting standards. Production processes for each project are carefully planned, documented and monitored utilizing various statistical process control techniques.

Production Capabilities:

Automated equipment can handle high volume casting jobs of up to 100,000 pieces per week

Manual machines for low volume jobs of as little as 500 pieces per year

Can cast from 0.02 to 10kgs

Single to Multiple Cavities

Most Aluminum die casting alloys are offered such as ADC10, ADC12, A380, 383, B390 (YL117), YL112, YL104

10 die casting & gravity casting lines. Each with an individual aluminum furnace which allows us to cast multiple alloys

7 sets of Cold Chamber Die Casting Machines. Range from 125 Tons to 800 Tons. And 3 sets of Gravity Machines.

| EQUIPMENT LIST | CAPACITY | QTY |

| COLD CHAMBER DIE CASTING MACHINE | 125 TONS | 2 SETS |

| COLD CHAMBER DIE CASTING MACHINE | 250 TONS | 2 SETS |

| COLD CHAMBER DIE CASTING MACHINE | 350 TONS | 1 SET |

| COLD CHAMBER DIE CASTING MACHINE | 650 TONS | 1 SET |

| COLD CHAMBER DIE CASTING MACHINE | 800 TONS | 1 SET |

| GRAVITY MACHINE | 750mm*630mm | 3 SETS |

| Tooling Leadtime: | 4 weeks |

| Tooling Lifetime: | 50000 shots to 500000 shots |

| Weight per unit: | Can cast from 0.02 to 10kgs per piece |

| Tolerance: | +/-0.05mm (secondary machining is available for tight tolerance) |

| Materials Applied: | ADC10,ADC12, A380, 383, B390 (YL117), YL112, YL104 |

| Casting Process: | Aluminum Die Casting 2) Machining: CNC turning, milling, drilling, grinding, cutting, reaming and threading 3) Surface Treating 4) Quality Checking and packaging |

| Surface Finish: | Shot blasting Parting line removal Chrome Plating Powder coating Painting Anodizing Passivation E-coating T-coating |

| Our Advantage: | 1. In house tooling design and fabrication 2. Owned die casting, polishing and plating workshops 3. Advanced equipment and excellent R& D Team 4. A broad variety of ODM& OEM product range 5. Strict quality Control System |

We will pay great attention to your any question or enquiry.

If any questions, please feel free to contact us at any time.

Tel: 86-592- 5209671

Fax: 86-592- 5209672

Ms.Anna Lin

Website:www.stickindustry.com / www.mould-casting.com Contact us if you need more details on Aluminum Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Die Casting、Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : 2) Aluminum Die Casting

Premium Related Products

Other Products

Hot Products

Magnesium Die CastingAutomotive Die CastingCustom high precision beautiful laser cutting decorative sheetCustom good quality profile angle aluminiumCustomized good precision powder metallurgy small module gearsCustom high quality cnc turning plastic pipe bushinghigh precision and good demand steel assemble partsCustom sheet metal precision stamping partCustom high precision brass engraving platesNice quality cnc machining titanium grade 5 motorcycle partschina low cost custom casting partscustom cnc machining drive shafthigh quality steel gear bicycle partsgood demand custon stainless steel metal fabricationhigh precision custom steel forged partscustom cnc machining ss304 parts